Geoscience Reference

In-Depth Information

u

u

ave

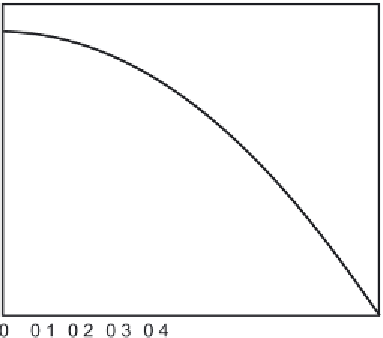

Figure 1.4 Profiles of

u/u

ave

in turbulent pipe flow,

Eq. (1.8)

, “flatten” as the

Reynolds number increases, making the mean shear and mean stress at the wall

much larger than in laminar flow with the same average velocity.

Pipes typically have some wall roughness, and

Figure 1.2

indicates that the mean

wall stress increases with that roughness. The explanation (

Kundu

,

1990

)isthat

immediately adjacent to the wall in

tu

rbulent pipe flow is a

laminar sublayer

of

thickness

δ

(τ

wall

/ρ)

1

/

2

the

friction velocity

. If the typ-

ical height

h

r

of the individual “bumps” or

roughness elements

on the wall is

much less than

δ

, wall roughness has minimal effect and the mean wall stress is

the viscous one given by

Eq. (1.9)

.Butas

h

r

approaches

δ

the roughness ele-

ments cause

form drag

through the pressure distribution on their surface, which

adds to the viscous drag and increases the friction factor

f

.When

h

r

is large

enough this form drag dominates and

f

ceases to change with

Re

, as indicated in

An analogous situation exists for the wall heat flux

H

wall

(watts m

−

2

). It is carried

entirely by the molecular diffusion process called

conduction heat transfer

:

∼

5

ν/u

∗

, with

u

∗

=

r

=

R

k

∂T

∂r

H

wall

=−

,

(1.10)

with

k

the thermal conductivity (watts m

−

1

K

−

1

). The heat flux is continuous at

the fluid-wall interface, but the temperature gradient there is discontinuous if

k

of

the wall material and the fluid differ. We shall consider the fluid side.