Information Technology Reference

In-Depth Information

9

K

2

!

G

7

Errors

Warnings

F

15

!

8

H

10

J

6

11

12

C

B

D

A

E

3

4

5

13

1

14

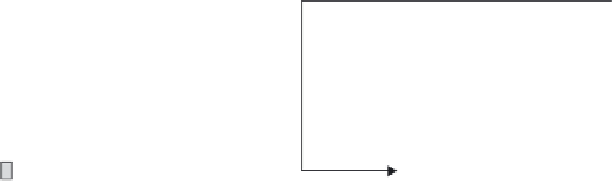

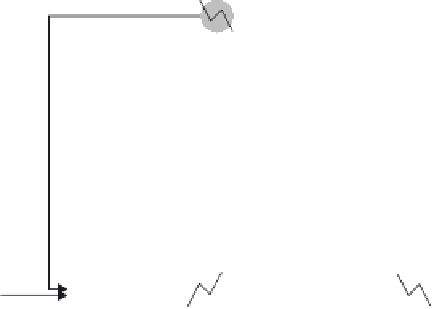

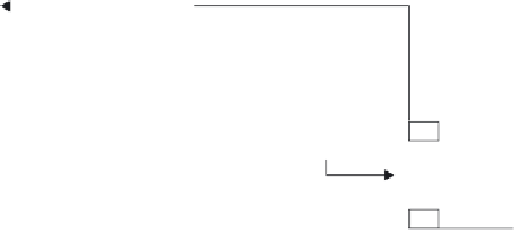

Figure 12.8

Execution errors identified.

from ExampleTwelve-3b enters the column. Because of this it will be necessary to

alter the sequence of calculations and provide good estimates for the new tear stream.

12.7.1 Selection of a Tear Stream

If the process flow diagram (Figure 12.8) is examined, one can see that guessing the

initial values of either stream 6 or stream 8 permits the sequential modular calculations

to pass through each block, finally arriving at the stream values guessed; however, using

stream 8 assures that only the organics pass through to the distillation column. One may

then copy the converged values from Example Twelve-3b stream 8 onto the appropriate

input of Example Twelve-4b. The definition of the tear stream, however, requires the

definition of a convergence block for stream 8. This is accomplished by opening the

Convergence entry under the list of specifications, opening the Convergence subentry,

and selecting New with the object manager. Figure 12.9 shows the selection of tear

stream with its convergence block.

12.7.2 Sequence of Calculations

The list of specifications also shows the entry Sequence, which when selected opens the

object manager to enable the creation of a sequence of calculations by selecting New.

The new execution sequence is shown in Figure 12.10. When this is executed, a satis-

factory solution is obtained for each operation. Results are given at Examples/Example

Twelve-4b.

12.8 REACTOR FEED

The process description, item 4, states: “Stream 13 is heated to 700

◦

C, producing

stream 5, which is combined with stream 4 at C, producing stream 6 at 560

◦

C”. In