Environmental Engineering Reference

In-Depth Information

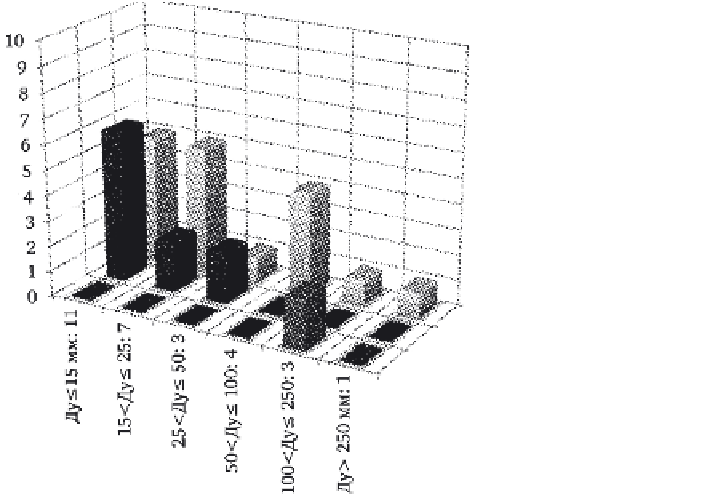

Welded joint: 17

Parent metal: 10

Flange seal: 2

1.26

Location of damage to the pipelines of the primary circuit

of NPP with PWR reactors.

based accident was applied in the design of NPP which is based on the

assumption that the main pipeline of the NPP fails extensively during

service plant, i.e. it is assumed that the probability of failure of the pipeline

is equation to 1

3, etc.

.

It is obvious that underestimation of the unreliability of passive elements

may result in lower estimates of the risk indicators NPP, and if the data on

the reliability of passive components are overestimated the PSA will lead

to overly conservative safety requirements.

Quantitative data on the probability of failure of equipment and pipelines

are needed not only for PSA. These data are of interest also for other tasks.

The limiting states of equipment and pipelines of the NPP are determined

by the criteria of strength, criteria of destruction, operating conditions,

and the state of the structure. Calculation of the maximum permitted

stress makes it possible to solve only one part of the problem of rational

selection of sizes of installations, namely: to determine the conditions

under which the installation should fail. The second, equally important

part of the problem is the question how to ensure that these conditions do

not occur, i.e. provide sufficient safety of equipment for the entire period

of its operation. This issue was solved, until recently, by introducing

more or less arbitrary factors - safety factors. A number of studies was

published in recent decades in which it was attempted to theoretically

develop more or less accurate methods for determining the safety factors

Search WWH ::

Custom Search