Environmental Engineering Reference

In-Depth Information

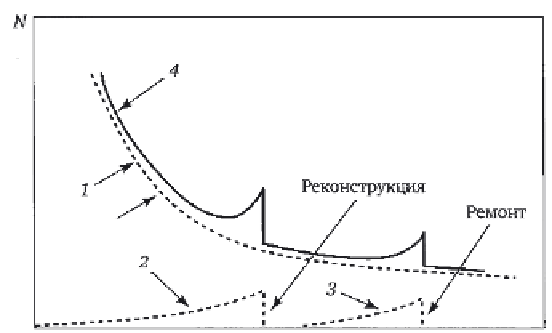

Reconstruction

Repair

Repair

Operating time

1.27

The defects detected during operation: 1) flaws inherent

in the manufacturing stage and missed in inspection; repair is

required; 2) increase in the number of defects associated with

deficiencies of design, require reconstruction; 3) increase of the

number of defects due to deficiencies of operation; require repair;

4) the total number of defects.

and allowable stresses. Procedures and methods of solutions used in these

studies somewhat differed from those used than in the traditional tasks

of ensuring the strength, namely, they were based on probability theory

and mathematical statistics. Here we must bear in mind that most of

the calculated values with which we have to operate in the calculations

of structural elements are not strictly defined and may have different

random deviations from their mean values. Therefore, each calculated value

should be expressed not by the number but by a distribution function that

characterises the probability of occurrence of all possible numerical values

of this quantity. It is also assumed that the given calculation situation will

be repeated many times and that the law of large numbers can be used here

to judge the frequency of occurrence of certain events on the basis of the

theoretically calculated probability of their appearance.

Another circumstance that requires estimates of the probability of

destruction of equipment and pipelines is the need to optimise the costs

of operating equipment and pipelines which, to ensure their safety, are

subjected to periodic non-destructive testing, hydraulic testing, technical

inspection, maintenance and repair work, upgrades. Obviously, in the case

of excessive optimistic estimates of strength reliability (failure probability

is zero) the above work seemed superfluous, and if exaggerated pessimistic

estimates are obtained (the probability of failure is 1), these measures

are insufficient. Obviously, the optimum organisation of operational

technologies of non-destructive testing, maintenance and repairs is only

possible on the basis of revised estimates of reliability and lifetime of

equipment and pipelines. As shown below, only the quantitative safety

Search WWH ::

Custom Search