Environmental Engineering Reference

In-Depth Information

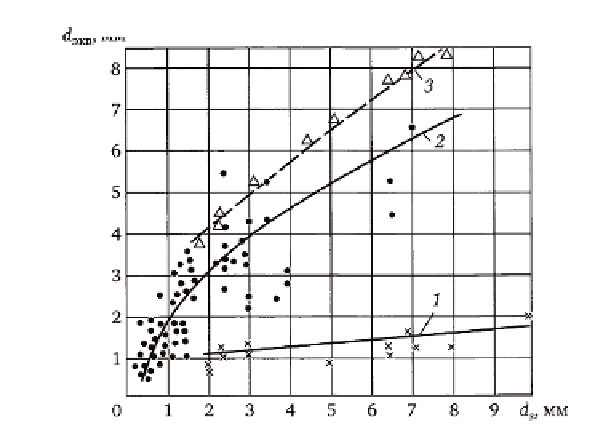

d

e

, mm

d

s

, mm

5.34

Correlation between the equivalent diameter

d

e

and its true

size in the cross section

d

s

: 1) cracks in inspection with a single

piezoelectric transducer, 2) volume defects, 3) crack in tandem

inspection.

Table 5.7

Information content of methods and the reliability of

detection of defects in welded joints of pipelines

Information content

Reliability of detection

compared with opening,%

Minimum detected sizes of inter-

nal defects, mm

Inspec-

tion

methd

Identification of

defects on the

basis of type and

appearance

Bulk

defects

(pores,

slag)

Planar defects

(cracks, narrow

incomplete fu-

sion, etc.)

Height,

Length

Width

Radio-

graphy

Good

0.1-0.2

0.1-0.2

0.1-0.2

85-90

65-75

Gamma-

graphy

Satisfactory

0.2-0.3

0.2-0.5

0.3-0.5

75-85

60-70

Ultra-

sonic

testing

Good for thick-

ness 40 mm

0.8

0.5

10.5

65-70

85-90

Colour

flaw test*

Satisfactory

0.3-0.4

0.5-1

0.5-1

75-80

55-65

Eddy

current

testing*

Cannot be distin-

guished

2-3

5-10

2-3

30-40

45-55

*Colour flaw test and eddy current testing for joints of pipelines with diameter 57-108 mm, thickness

3.52-4.5 mm

Search WWH ::

Custom Search