Environmental Engineering Reference

In-Depth Information

• material;

• type of weld;

• human factor;

is discussed below.

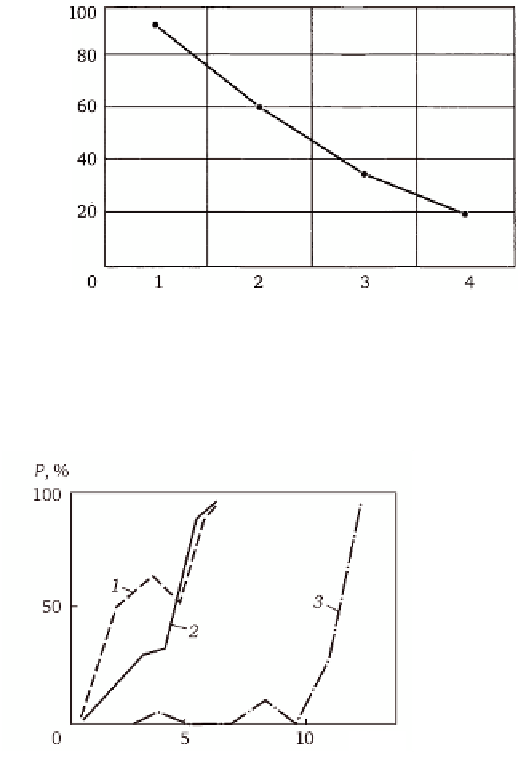

The effect of material on detectability is shown in Fig. 5.29. Comparative

analysis of the detection of discontinuities in relation to the physical

method of inspection was carried out in Ref. 82-86 and others. Figure 5.30

shows the results of the pilot study of detection of discontinuities by three

inspection methods, depending on their linear size

a.

86

The best detectability

was obtained for ultrasonic testing, the worst for radiography (RG).

Ultrasound (US), radiography and magnetic power (MP) inspection

methods were compared in Ref. 84 (Fig. 5.31)). In this case, the best

detection was shown by US inspection, the worst by MP inspection. The

Family of defects

5.29 Effect of material in which the defect is situated: 1) forged

steel, 2) fusion zone of the base metal with the weld; 3) clad

austenitic stainless steel, 4) weld.

a

, mm

5.30

Comparison of three methods of detection of discontinuities:

1) ultrasound; 2) dye penetrant, 3) radiography.

Search WWH ::

Custom Search