Environmental Engineering Reference

In-Depth Information

5.28

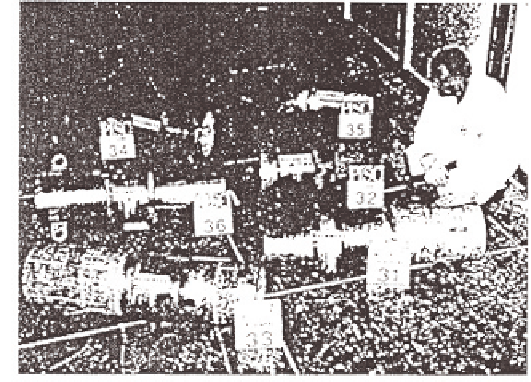

The experimental test specimens of austenitic steel (for

Fig. 5.26 and 5.27), PISC-III programme.

Systematic errors

are caused by factors operating in the same manner

in inspection under the same conditions or they change the results if the

inspection conditions change.

Random errors

lead to the spread of the results of repeated measurements

with respect to some mean value.

Misses

constitute gross errors associated either with the behaviour of

the operator or with undetected hardware failure.

The authors of this topic considered the effect of these errors in

conjunction with the state of inspection means, methods, and the type and

orientation of the defect.

V.N. Volchenko

75

analyzed the reliability of quality inspection and

singled out the errors of the first (excessive rejection) and second kind

(insufficient rejection). In this case, reliability

D

is estimated by

D

= 1-χ

α

-χ

β

, [5.2]

where χ

α

is the fraction of excessive rejection, χ

β

the fraction of insufficient

rejection.

In the PISC programme it was also attempted to isolate the impact on

reliability of such factors as the physical method of inspection, inspection

methods, excessive rejection and insufficient rejection, 'human factor', the

type of defect, material.

The dependence of the detectability of discontinuities in:

• physical methods of inspection;

• type and orientation of the defect;

• inspection methods;

Search WWH ::

Custom Search