Biomedical Engineering Reference

In-Depth Information

Bayly and his colleagues started research on the torsional axial model in

2001, [3] by developing a mathematical model of the torsional-axial coupling

that causes chatter in drilling. In this work, researchers have taken into

consideration three translations and one rotation, leaving the bending moments

out of the equation.

The equation of motion can be written as:

..

.

M x

C x

Kx

F

where

:

T

x

u

,

u

,..,

u

v

,

v

,..,

v

,

w

,

w

,..,

w

,

,..,

1

2

N

,

1

2

N

1

2

N

1,

2

N

T

F

F

,

F

,..,

F

,

F

,

F

,..,

F

,

F

,

F

,..,

F

,

M

,

M

,..,

M

x

1

x

2

xN

y

1

y

2

yN

z

1

z

2

zN

1

2

N

u, v, w - deflections in x, y, z , θ- twist about the axis.

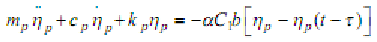

The time varying component of the modal equation can be written as:

where: m, k, c - modal mass, stiffness and damping, ʱ = C

2

/C

1

+ θ

Np

R

av

, θ

Np

-

torsional axial coupling parameter, R

av

- average radius of the cutting force,

C

1,

C

2

-tangential and thrust forces per unit area of uncut chip, b- radial depth of

cut, η

p

- modal coefficient of the p

th

mode, η - time delay between passage of

cutting edges of the drill.

The difference between this equation and classical chatter equations is in

the constant ʱ which includes the effects of tangential and axial forces as well

as torsional axial coupling. Another difference lays in the fact that -ʱC

1

which

presents the effective cutting pressure is not always positive as it is in milling

and turning operations.

Predictions of stability regions have been done by frequency domain

analysis and confirmed by both experimental work and computer simulations.

The drill dynamics were described by the Frequency Response Function

(FRF), which is defined as displacement at the given location in response to a

unit force, as a function of excitation frequency.

Radial depth of cut is expressed as: