Biomedical Engineering Reference

In-Depth Information

chisel edge and flank surfaces cause damping in the system. However, due to

the fact that these investigations have been conducted in an unconventional

way, the results are not completely trustworthy since there is rarely a situation

where one would have to rotate the workpiece instead of the drill. By using the

stationary tool, the effect of the spindle and bearings was neglected, neglecting

the conventional problems in drilling.

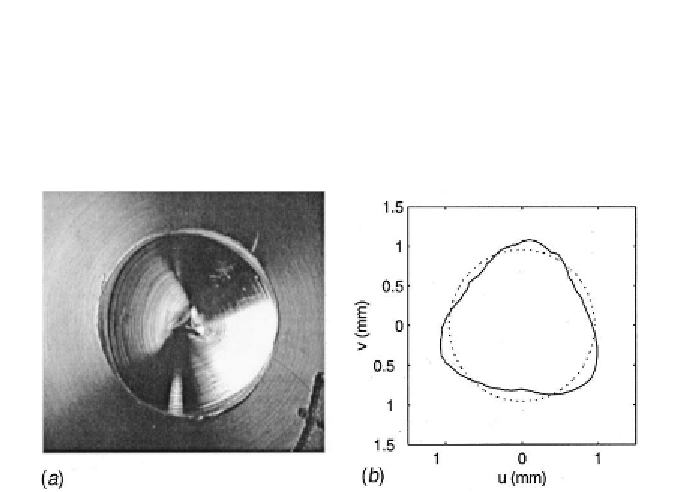

Figure 2. Photograph and measured profile of a three-lobed hole [12].

The state of the art in turning, milling, drilling and grinding has been

presented by reference [13], covering present mathematical models and chatter

suppression methods. The first part of the paper deals with the dynamics of the

orthogonal metal cutting and chatter stability lobes, defining the linear

dependency of the cutting forces on the width of cut and feed per revolution

(or static chip thickness):

F

K ah

0

F

K ah

0

where: a - width of cut, h

0

- feed per revolution or static chip thickness , Kt , Kr

- tangential and radial cutting coefficients.

The dynamic chip thickness and transfer function of the closed loop

system have been defined as: