Biomedical Engineering Reference

In-Depth Information

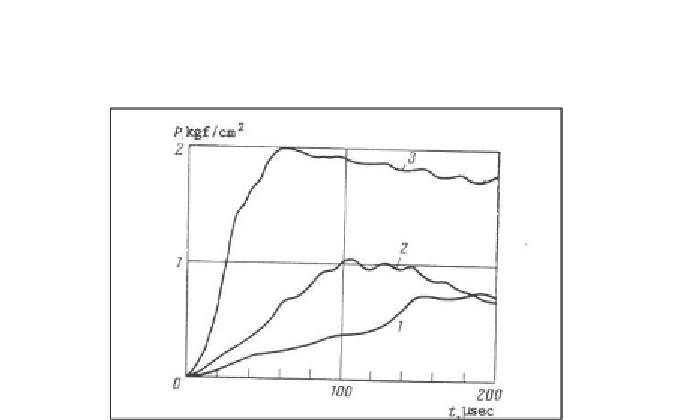

thickness of the Mylar burst disc was not provided. In Figure 18, curve three

represents data for the Mylar burst disc, while the curves labeled with numbers

one and two represent rubber burst discs (Baksht and Fedyunin, 1989).

Reproduced with permission. Copyright retained by Inderscience Publishers.

Figure 18. Pressure Rise vs. Time for Burst Discs.

2.4. Summary of the Literature Review

The study of particle impacts into substrates with then intention of

developing surface coatings dates back to the beginning of the process now

known as thermal spray, first developed by Max Ulrich Schoop and filed for

patent in 1909 (Kogelschatz, 2004). Schoop realized that by firing molten

metal particles at high speeds into a substrate, it was possible to produce a

surface coating of the particle material onto the substrate. This first process

was of the type known as molten metal flame spray, and soon thereafter

Schoop began refining processes and further developed powder and wire

metallizing (Hermanek, 2002). Since the inception of this technology,

refinements and improvements have been made, as well as new methods to

achieve surface coating using thermal spray. All of these methods have in

common the input of heat into the process to accelerate the particles in molten

or semi-molten form.

In the 1980s particle impacts at low temperature became an area of

interest. Anatolli Papyrin (2001) discovered the possibility of depositing

particles to create surface coatings in the solid state. This became an area of

interest because particle microstructures can remain intact after forming the