Biomedical Engineering Reference

In-Depth Information

5.

D

ISCUSSION

It can be seen from the above analysis that despite the extremely high

strain rates imposed due to high speed cutting, macroscale equations can be

applied accurately and produce impressive results. The most significant

differences however appear in the following categories: strain rate, scallop

height, and chip type. Many of the forces are of a similar order of magnitude

offering no significant difference between macro low speed and micro high

speed machining. This is important during tool design as small tools must

absorb the same impact forces as larger tools do during impact. However,

when considering the strain rate it can be seen during micro high speed

machining the strain rate is 8333 x 10

3

s

-1

compared to the macro low speed

case of 667 x 10

3

s

-1

, a 12.5 times increase which relates directly to a 12.5

increase in speed from 20,000 rpm to 320,000 rpm.

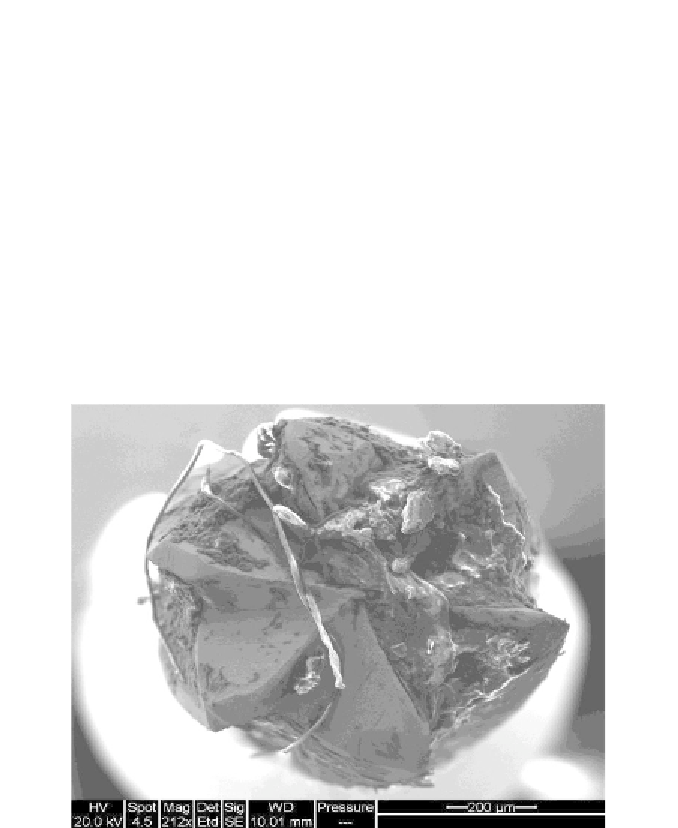

Figure 7. View of cutting edges and adherent bovine femur chip showing fine striations

of lamellae. Reproduced with permission. Copyright retained by Inderscience

Publishers.

The increase in strain rate is directly related to the increase in cutting

speed, this is expected as the cutter is imparting the strain and therefore a rate

of strain to the material. The lamellae spacing Δy in equation 20 has a

significant effect on the strain rate, comparing macro and micro scale chips it