Environmental Engineering Reference

In-Depth Information

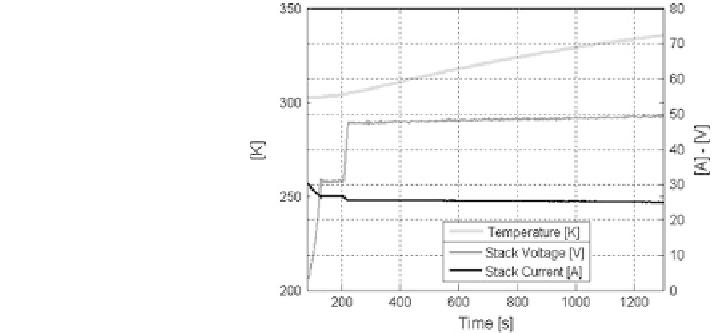

Fig. 6.18 Acquisition versus

time of stack voltage, current,

and temperature during a

steady-state test at 1.2 kW

(R = 1.9)

in particular those closer to the end plates, are more sensitive to flooding since

purge intervention permits a clear voltage recovery.

The effect of the humidification strategy can be deducted by analyzing a third

acquisition window (2180-2400 s) for the experiment of Fig.

6.11

, shown in

Fig.

6.16

, where the individual cell voltage and hydrogen pressure measured at

anode inlet are reported versus time.

The Fig.

6.11

evidences that during this time window three different steady-state

conditions are reached at 338 K, when the stack load decreases from 1.5 to

0.15 kW. In detail, the stack current is hold at 40 A (1.1 kW) for about 60 s, at 23 A

(0.7 kW) for 40 s, and finally at 5 A (0.15 kW) for 30 s. During the entire test phase

both purge and humidification management appear to be suitable for the optimal

stack operation. This is evidenced by maximum C

v

peaks of 1.5% in correspon-

dence with purge intervention (at 2250 s, Fig.

6.12

) and 1.4% at 2315 s due to

external humidification, whose effect becomes more evident at lower stack power

(from 0.7 kW), when the purge is not utilized and the minor water production

enhances the membrane dehydration. The voltage recovery of individual cells due

to external humidification is detailed in Fig.

6.17

, where the voltage is reported for

three instants, just before the second cell voltage reduction (2280 s in Fig.

6.16

),

then for the instant corresponding to the maximum of this peak (2312 s), and for the

final value after the stabilization of the voltage (2315 s). In spite of the particular

sensitivity of some cells (N.6 and N.28) to water management, the C

v

values result

acceptable also for the last phase of the experiment of Fig.

6.11

.

In order to clarify the effectiveness of the external humidification strategy in

stack managing, a further experiment is shown in Figs.

6.18

and

6.19

. This test is

effected in a steady-state condition corresponding to the maximum efficiency of

the FCS at 1.2 kW and R = 1.9. Stack current, voltage, and temperature are

reported as function of time in Fig.

6.18

, while C

v

and hydrogen pressure are

shown in Fig.

6.19

.

During this test, the stack temperature is left rising from 303 to 338 K, with a

variable increase rate from 2.5 to 1.5 K/min. The regular stack operation is