Environmental Engineering Reference

In-Depth Information

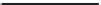

is shown in

Figure 4.1

. As the contact angle increases, the more hydrophobic the

surface becomes, and the macrofouling decreases.

Table 4.3 Biofouling data (micro and macro fouling) after one year of immersion of

various polymers and composites in surface waters of the Bay of Bengal, South India

Name

of the

polymer

Fouling

load

(mg/cm

2

)

TSS

(mg/cm

2

)

Protein

(mg/cm

2

)

Carbohydrate

(mg/cm

2

)

Chlorophyll

a (µg/cm

2

)

Barnacle

(Number/

plate)

Polychaetes

(Number/

plate)

SR

36.38 ±

0.63

24.40 ±

2.40

1.02 ± 0.14

0.54 ± 0.04

0.54

0.3 ±

0.20

4.0 ± 2.30

PU

100.58 ±

35.18

28.50 ± 4.1

1.15 ± 0.25

0.48 ± 0.02

0.519

14.3 ±

5.9

10.3 ± 2.1

PET

134.07 ±

46.90

29.40 ± 1.1

1.25 ± 0.03

0.63 ± 0.04

0.6

11.7 ±

5.0

5.7 ± 2.1

SF

163.80 ±

28.26

28.40 ± 1.5

1.32 ± 0.07

0.67 ± 0.02

0.625

17.0 ±

3.0

8.7 ± 3.8

GFRP

164.62 ±

36.25

25.20 ± 3.5

0.97 ± 0.40

0.51 ± 0.10

0.867

23.7 ±

9.1

3.7 ± 1.5

CFRP

203.23 ±

38.70

27.5 ± 3.5

1.13 ± 0.04

0.63 ± 0.03

0.467

17.0 ±

5.7

12.5 ± 3.5

180

160

140

120

100

80

60

40

20

0

40

50

60

70

Contact angle

80

90

100

110

Figure 4.1

Number of macrofoulers at the end of three days placement, on

polyvinyl chloride, PP, HDPE, PC, GFRP, Telon

®

, SF, acrylic, silicone, PU,

polydimethylsiloxane (PDMS) and polyester (correlation coeficient = 0.60)