Environmental Engineering Reference

In-Depth Information

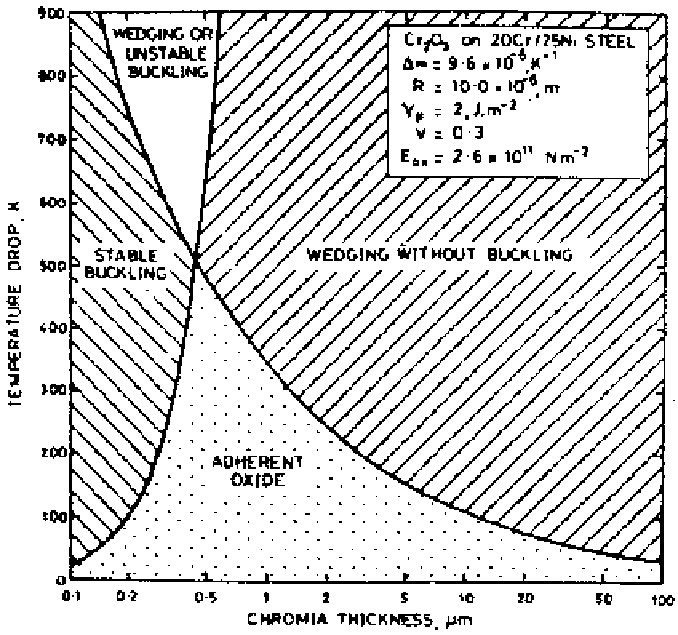

Figure 5.30

Spallation map for 20Cr-25Ni steel cooled from 1173 K [Ref. 51].

larger than the detection limit of 0.1

m. Such alloys have generally been found

to form a protective oxide thickness of around 10

µ

m under typical service condi-

tions, leading to the inevitable conclusion that spallation by buckling is unlikely

to be relevant in industrial usage.

The wedging line as shown in Fig. 5.30 is calculated using an effective fracture

energy (

µ

γ

F

)of6Jm

2

. This value is in reasonable agreement with spallation data

for a chromia forming austenitic steel but it also includes a contribution from

creep deformation of the alloy. Identification of the appropriate value of

γ

F

is

rather difficult because many factors, notably creep deformation, are involved.

Indeed the energy of adhesion at the oxide-metal interface and the surface energ-

ies of the oxide and metal phases may only be minor components of the actual

total energy required to produce decohesion and subsequent spallation.

The benefits of a weak creeping substrate and a small defect size at the oxide-

metal interface can best be illustrated by a modified spallation map as shown in