Environmental Engineering Reference

In-Depth Information

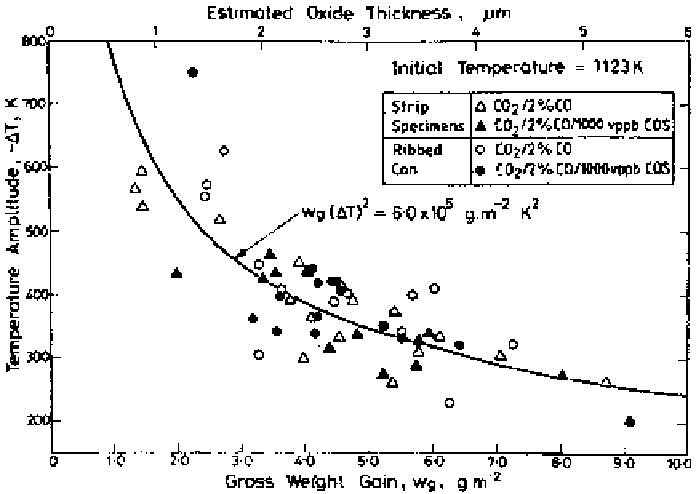

Figure 5.29

Variation of critical temperature drop to initiate chromia spallation from

austenitic steel as function of gross weight gain or oxide thickness [Ref. 51].

and spallation occurs by the formation of cracks in tensile regions around the

buckle. This buckle configuration is stable, i.e., it will not extend laterally by

tensile crack growth along the oxide-metal interface. Such lateral growth will

occur in a small region as shown at the top of the map bounded by the buckling

and wedging lines after their interaction. The dominant failure mode for the ex-

ample cited is the wedging as indicated by a large area to the right-hand side of

the map. Of much interest is the region to the bottom of the map within which

the oxide layer suffers no significant mechanical damage. Alloys having high

spallation resistance will have this area in an enlarged form.

A significant feature of Fig. 5.30 is the rapid increase in the value of

T

c

for

buckling with only modest increases in oxide thickness, e.g., over the range 0.5-

1.0

∆

m. A consequence is that buckling failure is likely to be important only for

thin layers or for those that already exhibit large-scale decohesion. This appears

unlikely in alloys that have been designed for high-temperature oxidation resis-

tance where extensive interfacial void formation is rare. A recent study for the

interfacial voids during high-temperature oxidation of alumina forming FeCr

alloy (Fe-22Cr-5A1) and Haynes 214 (Ni-16Cr-4.5A1) alloys exhibited nothing

µ