Environmental Engineering Reference

In-Depth Information

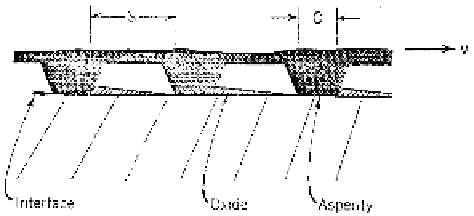

Fretting is also a wear phenomenon that occurs between two mating surfaces

under loading and having a relative slip of extremely small amplitude. The slip

is usually oscillatory as, for example, that caused by vibration. Under such condi-

tions, asperities, i.e., the minute protrusions of one surface ''plough'' through

the mating surface dislodging metallic particles or breaking the protective film

(Fig. 3.31). Fretting corrosion is the aggravation of this phenomenon in the pres-

ence of a corrosive liquid. Here also, like corrosive wear, either a mechanism of

oxidation-wear or wear-oxidation operates.

In fretting corrosion the damage is characterized by discoloration of the metal

surface and formation of pits. Fatigue cracks may eventually nucleate at the pits.

In ferrous materials, fretting corrosion creates debris of reddish brown ferric ox-

ide particles. The consequence of fretting corrosion is loss of dimensional accu-

racy, loosening of the parts, sometimes seizure of the parts because of the accu-

mulation of corrosion products, and, at times, fatigue failure. The magnitude of

damage increases with increasing load, but decreases with increasing temperature

and increasing moisture, indicating that the mechanism is not fully electrochem-

ical.

Fretting and fretting corrosion are encountered in joints, connecting rods,

shrink fits, oscillating bearings, splines and couplings, and in many parts of vi-

brating machinery. Fretting often occurs in bearings and other contact points

during shipping of components and equipment.

Any measure that reduces wearing action would minimize fretting corrosion.

Lubrication of contacting surfaces is beneficial. That is why increased moisture

during rainy season provides a lubricating effect to reduce the extent of damage.

Reducing the load is effective, but at the same time, increasing the load and thus

reducing relative slip is also helpful. Separation of surfaces by insertion of a

material of high elastic strain limit, such as rubber or Teflon, prevents fretting.

In press-fitted assemblies, induction of residual stresses by shot peening or other

Figure 3.31

Fretting action at a metallic surface with oxide layer.