Environmental Engineering Reference

In-Depth Information

treatments is helpful to prevent fatigue crack propagation initiated by fretting.

Elimination or reduction of vibration would be ideal to reduce relative slip, but

often this measure is not practicable.

3.8.6 Practical Examples

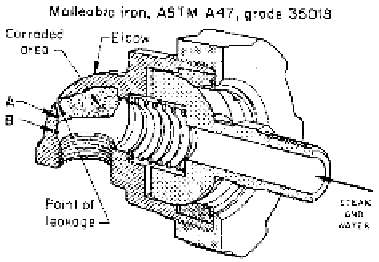

Leakage was detected in a malleable iron elbow after only 3 months in service,

whereas the life expectancy was 12-24 months (Fig. 3.32) [2]. The component

was exposed to alternate steam and cooling water supply for at least 16 h a day.

Investigations revealed a ferritic malleable iron structure, which was less resistant

to erosion corrosion than pearlitic malleable iron. A proper heat treatment im-

proved the performance.

Figure 3.33 illustrates a cavitation damage of a pump impeller made of 55Ni-

21Cr-3Mo-3.5Cu-1W alloy working in a water contain 550 ppm chloride at 44

C

[6]. Closely spaced pits are clearly visible. It may be noted that the material used

belongs to the group of most erosion corrosion-resistant materials. Change in

operating conditions of the pump was recommended as a remedial measure.

°

3.9 CORROSION CRACKING

Many metals and alloys develop cracking under the combined action of stress

and corrosion. Corrosion-induced cracking processes are categorized as:

1.

Stress corrosion cracking,

2.

Corrosion fatigue, and

3.

Hydrogen-induced cracking.

Figure 3.32

Section through the malleable iron elbow showing the area of erosion

corrosion attack.