Environmental Engineering Reference

In-Depth Information

In the example shown in

Figure 13.24

, the upstream coffer dam has been designed to

divert the 1 year summer (dry season) flood and the main coffer dam the 5 year winter

(wet season) flood. There is therefore some risk that it will be overtopped.

It has been common practice in Australia since the late 1960s to provide protection to

the coffer dam and/or to the main embankment to prevent failure in the event of overtop-

ping. This is done by covering the downstream face of the coffer dam or the main

embankment with steel mesh or rock filled gabions, which are anchored into the slope

with steel reinforcing rods. If this reinforcement is provided on the main embankment it

can be designed so that much greater return period floods can be accommodated, e.g. 1 in

100 year or 1 in 700 year floods. Whether these are acceptable should be determined in a

risk analysis framework.

The use of such steel mesh reinforcement has allowed use of significantly smaller diver-

sion tunnels and upstream coffer dams, with resultant savings in project cost. The design,

construction and operation of steel mesh reinforcement is described in ANCOLD (1982)

and ICOLD (1984). As detailed there, up to 1982 the method had been used on 50 dams;

41 in Australia, 9 in other countries.

The following outlines only the broad principles and for design purposes reference to

the ANCOLD or ICOLD publications is recommended.

13.8.2

Types of steel mesh reinforcement

The technique has evolved over several years, being modified to take account of lessons

learnt from failures and to reduce the costs involved. Some early systems failed during

operation, due to:

- Damage of relatively lightweight steel meshing, by floating logs, or by boulders from

the surface of the dam, e.g. Cethana Dam (HEC, 1969);

-Erosion of the contact between the steel meshing and the downstream abutment due to

inadequate anchorage, e.g. Xonxa Dam (Pells, 1978).

A design which took account of these early problems, and successfully withstood 33

hours of overtopping, up to 2.5 m deep when the dam was 20 m high, was that employed

at Googong Dam (Fokkema et al., 1977).

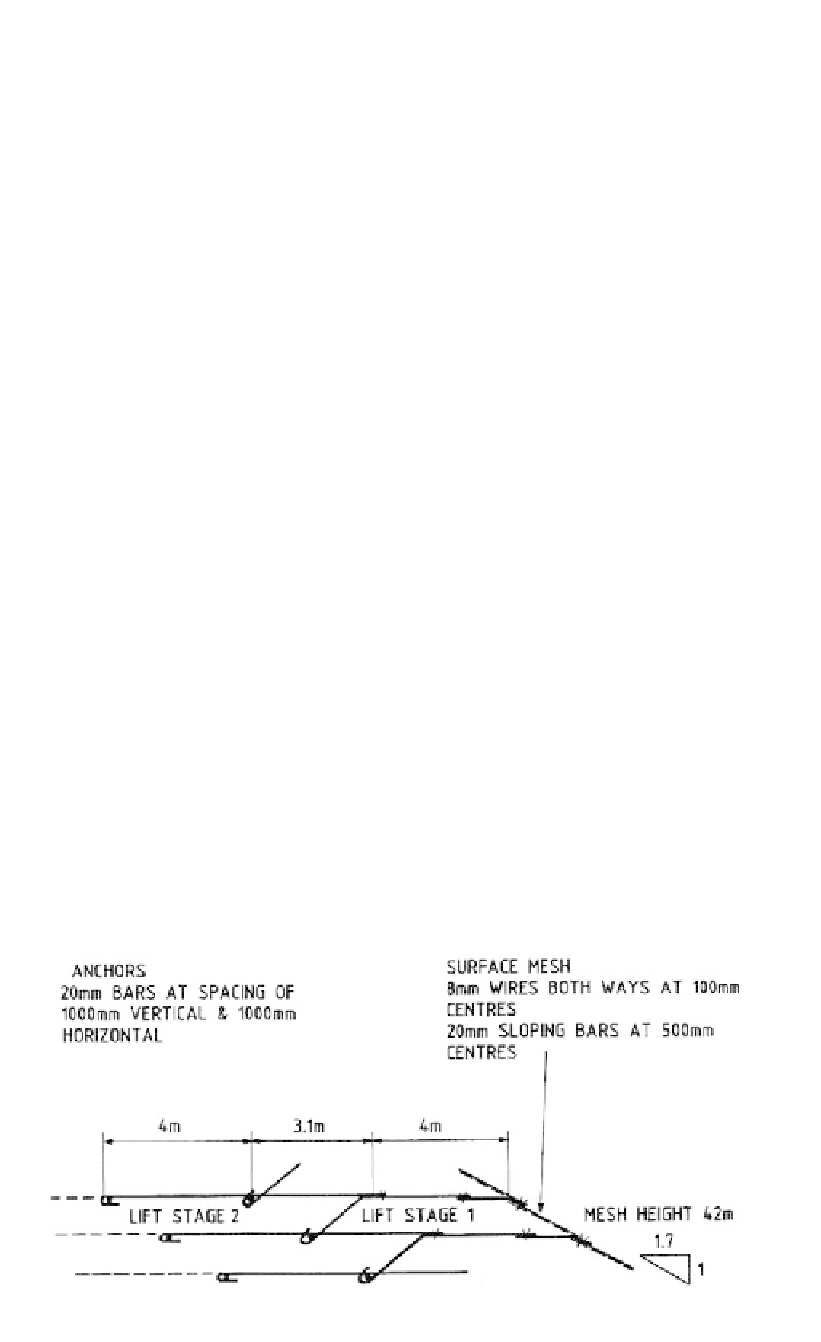

Figure 13.25 shows the meshing system for Googong Dam.

Figure 13.25.

Steel mesh reinforcement for Googong Dam (Fokkema et al., 197; ANCOLD, 1982).