Environmental Engineering Reference

In-Depth Information

There are several features of the design:

- The continuous concrete protection around the toe;

- The cranked anchor system for the avoidance of progressive failure;

- The combination of a medium duty surface mesh with small opening size and an over-

lay of fairly closely spaced (500 mm centres) sloping bars to protect the mesh;

- The return of the sloping bar into the fill for tensioning to the anchor prior to welding

the connection between the two;

- Infilling voids in the face rockfill with concrete to lessen the chances of individual rocks

being plucked out (but not too much so as to lower the through flow capacity of the

rockfill);

- Being able to secure the protection at the top of each layer as it is approaching comple-

tion, with the use of temporary gabions on the abutment section of each layer to direct

the flow to the centre of the dam.

The Hydro-Electric Commission of Tasmania have carried out a significant amount of

tems they have developed to cope with their particular problems - regular overtopping, par-

ticularly of coffer dams, and heavily timbered catchments, which give potential for damage

during overtopping by floating logs.

These systems all use cylindrical gabions fabricated from 50 mm square mesh with

5 mm wires both ways (4 mm for Mackintosh Coffer Dam).

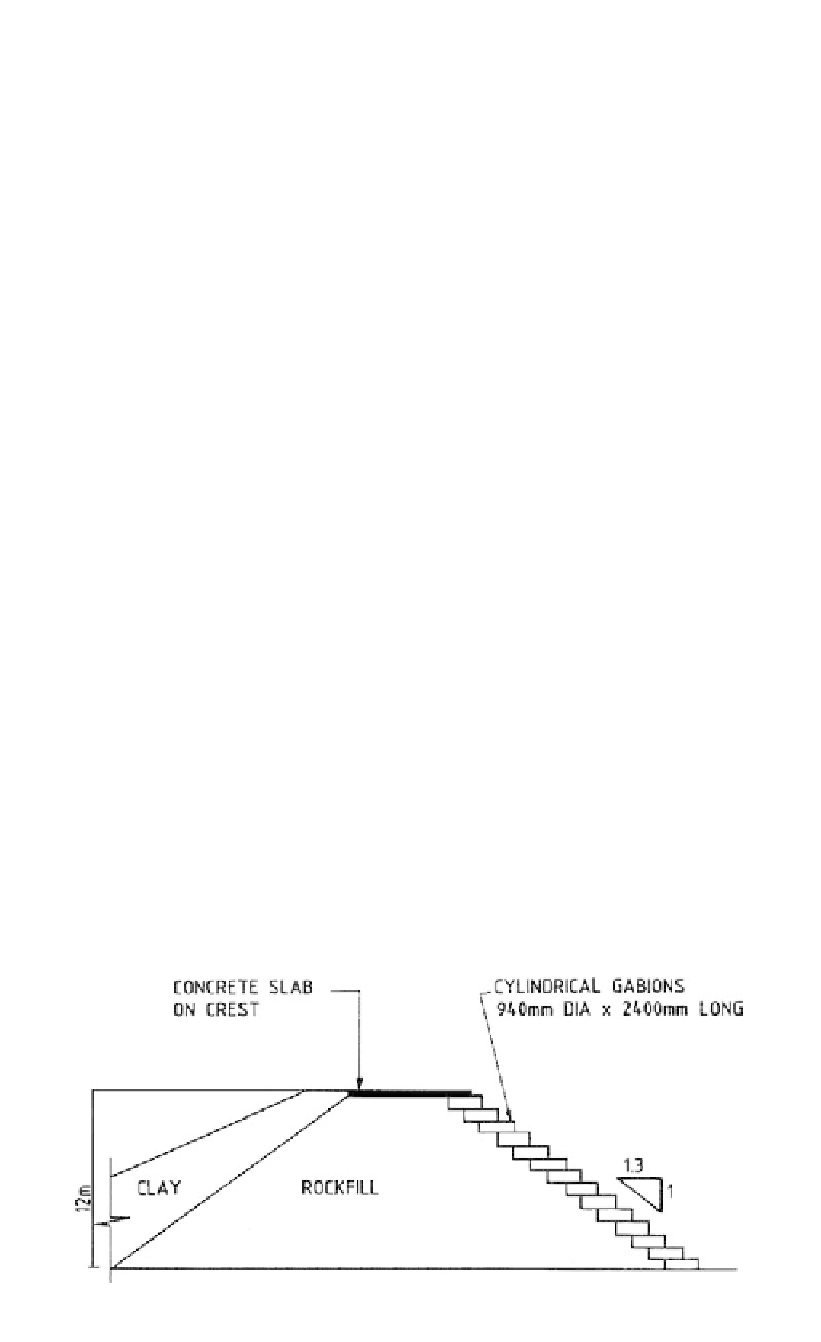

For the Mackintosh Coffer Dam (Figure 13.26), a concrete slab was placed over the

rockfill crest to secure the top row of gabions and prevent overflowing water from enter-

ing the downstream rockfill zone through the crest. Model tests were carried out to meas-

ure the pore pressures used in stability analysis which showed that anchor bars were not

required. The coffer dam was overtopped by small floods several times without any dam-

age being sustained. A similar system has been used on other HEC dams.

For Mackintosh Dam the downstream face of the dam was protected to a height of 21 m.

As shown in Figure 13.27 this took the form of a vertical wall of gabions anchored to dowels

grouted into the rockfill. The protection was made vertical to keep the many floating logs that

were expected to be carried during floods clear of the face. The triangular wedge of rockfill

forming the toe of the dam was placed after the embankment was above the 100 year flood

level. The dam was overtopped once during construction but only to a depth of 300 mm.

The system was found to be costly mainly because of the very substantial anchors

required and the full strength bolted connections. Although this type of connection was

Figure 13.26.

Steel mesh reinforcement for Mackintosh Coffer Dam (ANCOLD, 1982).