Environmental Engineering Reference

In-Depth Information

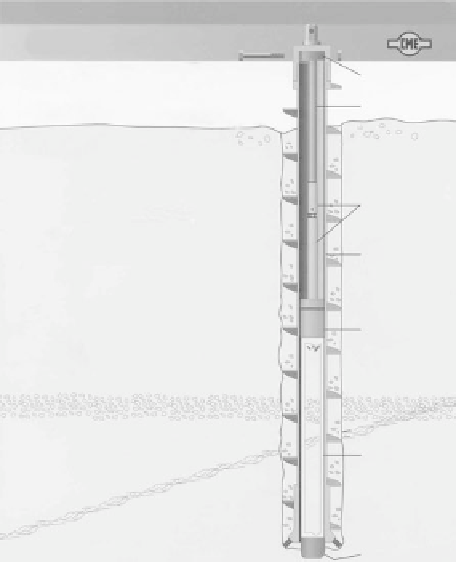

CME

Bearing Head

Continuous Sample

Tube System

Rod to cap

adapter

Drill rod

Adjustment Rod

Hollow-stem

auger

Bearing

Assembly

Sample tube

Sample shoe

Figure 5.13.

Hollow auger continuous sample tube system (courtesy CMEC).

bailer. If the hole is dry, water is added to aid the bailing. As the hole is advanced steel

casing is driven to preserve the hole. The method is slow, but is effective in penetrat-

ing gravels. It should be appreciated that the penetration process involves a reduction

in particle size and may mix material from several layers. The grading of samples

recovered from cable tool drilling may be different from that of the natural material.

(b)

Cable-tool Tube (also called Shell and Auger) drilling

. This method described by

Wilson and Hancock (1970) uses a cable-tool rig as in

Figure 5.14a

but the hole is

advanced and sampled by driving 100 mm diameter sampling tubes (Figure 5.14b and

Figure 5.15

). After each 300 mm long tube is driven the sample is extruded into a plas-

tic sleeve, labelled and placed into a core tray. Before the next sample is taken the hole

is reamed out using a slightly belled cutting shoe. When required, due to hole collapse

or to seal off groundwater flow, the hole is reamed further and casing is driven. No

drilling fluid is required. The method provides a continuous geological record in most

soil types, a record of moisture content changes and also of the position and source

level of any groundwater inflows (Figure 5.15). The tube samples are too disturbed

for triaxial or similar testing but the fabric and defects in soils are preserved and can

be seen when the samples are split. If rock, coarse gravel or boulders are met, these

materials can be penetrated by the bit and bailer method.

Cable-tool drilling can be used for investigating the cores of existing dams as it is a dry

method and will not induce hydraulic fracture. However it is slow and expensive com-

pared to auger drilling. Completion of such holes should include backfilling with

grout in stages designed to avoid hydraulic fracture.

(c)

Hammer (or Impact) Drilling.

Machines for this type of drilling range from the very small

“air-tracks” through larger versions to large truck-mounted downhole hammers with