Environmental Engineering Reference

In-Depth Information

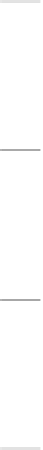

Log from

augered

borehole

Log from

static cone

penetrometer

Depth

0m

Water

LEGEND

Sand

5m

Silty sand

Sandy silt

10 m

Clayey sand

Sandy clay

Clay

15 m

Figure 5.12.

Log of sandy and clayey soils below the water table from an augered borehole and from

static cone penetrometer.

a rapid method of establishing the depth and general properties of the material overlying

rock which will be investigated in more detail by some other method.

A major difficulty in auger drilling in cohesionless soils or soft clays is the stability of

the sides of the drill hole particularly below water. Figure 5.12 shows a log prepared from

an augered drill hole in sandy soils below the water table, compared with the log of a

nearby static cone penetrometer probe. Mixing and collapse of the hole have led to gross

inaccuracies in the auger hole log. Auger drilling in non-cohesive and weak soils is there-

fore restricted to above the water table.

Hollow flight augers have the advantage of providing support for the hole in these con-

ditions and allow sampling through the augers. However the action of removing the plug

at the end of the auger will often loosen and disturb the soil below the auger and hollow

flight augers are not recommended for drilling in cohesionless soils, particularly if they are

loose, or in weak clays.

The development of large diameter hollow auger drilling has enabled the recovery of con-

tinuous core with effectively undisturbed soil samples up to 300 mm in diameter (

Figure 5.11

and

Figure 5.13

). This equipment is used to drill up to 80 m deep in dam cores in the USA.

Hollow flight augers are an acceptable technique for drilling in the core of existing dams

because no drilling fluid is used which can cause hydraulic fracture. However the holes must

be carefully backfilled in stages with cement/bentonite grout to avoid hydraulic fracture.

5.9.4

Percussion drilling

There are three main types of percussion drilling as follows:

(a)

Cable tool (bit and bailer) drilling

(

Figure 5.14a

)

involves the successive dropping of

a heavy chisel type bit to the bottom of the hole. The fragments are recovered using a