Java Reference

In-Depth Information

The supervisory console should visualize the paint tonality in accordance

with the paint composition of the mixture tank. The output flow and

volume of the spray pump should be consistent with the values set by the

technician in the supervisory console.

■

13.3

■

Architecture and planning

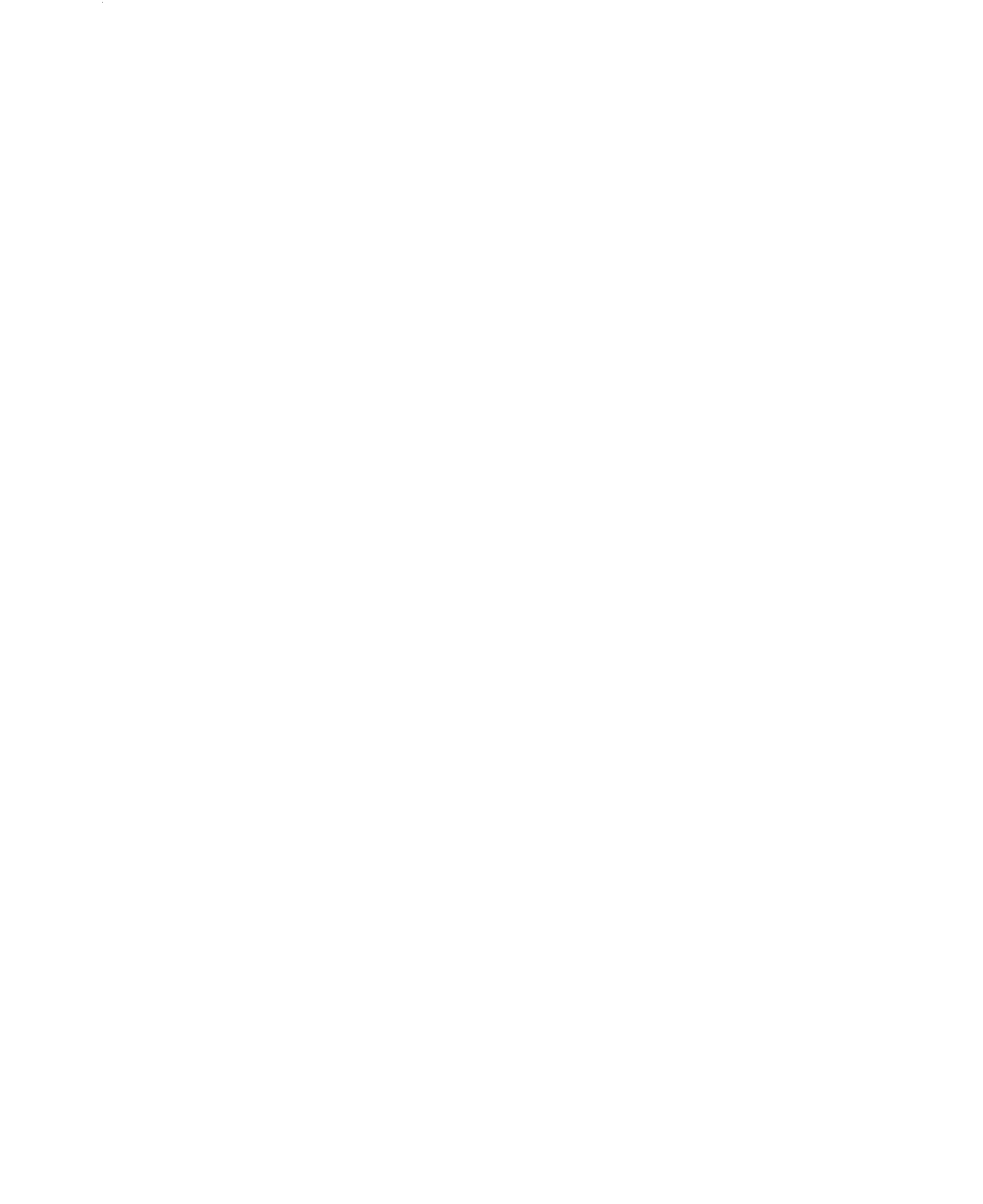

The system architecture is made up of four main subsystems as described in

Figure 13.3. The simulator component models the physical equipment of the

work cell and enforces the physical consistency constraints.

The tank controller and mixture controller components monitor the paint

level in the tanks and control the input and output pumps in order to regu-

late the paint level. The mixture controller sends commands to the tank

controller in order to regulate the composition of fundamental colours in the

mixture tank. Every controller has a local console that allows the technician

to operate the equipment directly.

The supervisory component implements the supervisory console that

displays the tonality of the paint in the mixture tank and allows the tech-

nician to change the colour composition and to regulate the output flow and

volume of the spray pump.

The development process of the SCADA system is organized into three

phases that produce three prototypes.

Prototype 1: Work cell simulation

. A standalone application that simu-

lates the physical work cell. A graphical user interface depicts the equip-

ment as in Figure 13.1 and allows the user to open and close the pumps

manually.

■

sets colours

controls flows

controls flows

Tank controller

Mixer controller

Supervisor

controls flows

monitors tanks

controls flows

monitors tanks

monitors

tanks and

pumps

Simulator

Figure 13.3

The system architecture