Civil Engineering Reference

In-Depth Information

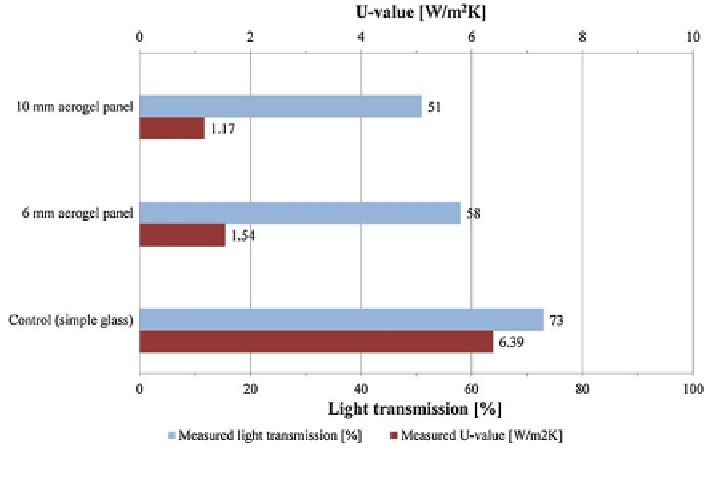

Two prototypes of the twin-wall sheet were manually filled with 3-mm-diam-

eter aerogel granules; the first one with a 6 mm aerogel thickness and the second

one with 10 mm thickness. Both the prototypes were inserted in a test window,

sealed around the edges, and attached to the internal face of the frame using duct

tape. A 15-mm air gap was created between the panels and the existing glazing.

In situ U-values of the prototypes and the control panel were calculated, by

measuring external and internal temperatures by thermocouples, and the heat flux

by Peltier modules thermally bonded to the centre of each sample. The light

transmission was also measured by lux sensors in the centre of each panel.

The average heat flux through the control glass during the test period (from

20 February 2010 to 1 March 2010) was about 18 W/m

2

, significantly higher than

the one through both the prototypes: the 6-mm aerogel panel reduced heat flux by

approximately 73 % and the 10 mm aerogel panel by approximately 80 %.

The light transmission in five different test periods was measured. Results show

that the proportion of light transmitted does not depend on the period, and the

average value through the 6-mm aerogel panel, 10-mm aerogel panel, and the

control was, respectively, 58, 51, and 73 %.

A summary of the results of the study is shown in Fig.

18

.

Very significant thermal performances were found for aerogels: a 80 %

reduction in heat loss with respect to single glazing can be achieved by designing a

purpose-built retrofit solution containing aerogel, with an acceptable reduction in

light transmission.

Fig. 18

Summary of in situ testing results (adapted form Dowson et al.

2011

)