Civil Engineering Reference

In-Depth Information

to absorb expansion. Others leave air between. Still

others lay the stone right against it, ignoring expan-

sion. I use tile, bringing the stone close, filling the

space here and there with gravel. Seal around the top

with masonry mortar, so rain won't sog everything.

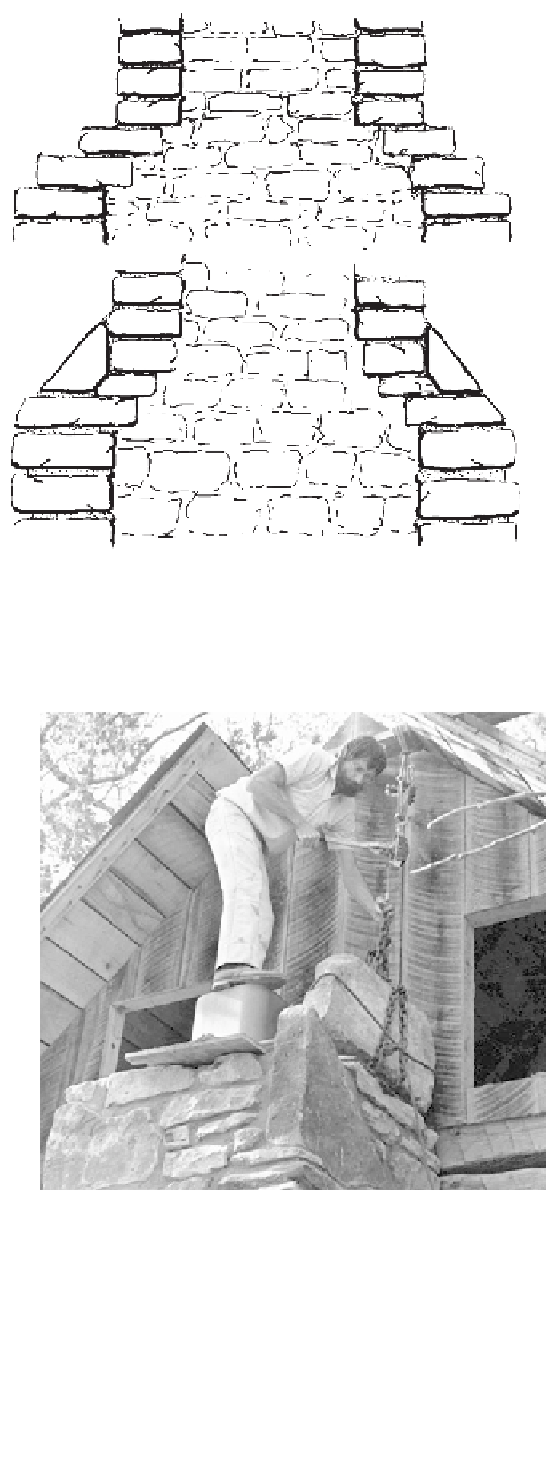

Step the chimney in a foot or so on each side above

the large chamber. I usually do it in two or three steps,

for 45-degree shoulders here, or slope the shoulders

with large slabs of stone.

At the roofline, whether inside or outside the house,

you'll need to flash to keep out leaks and prevent wood

decay. Set aluminum, galvanized or copper flashing

into the horizontal joints in the stonework, and bend

it down over counter-flashing up from the roofing.

At the ridge, a piece will have to be fabricated, so it

can be set in stone and then cut, bent more than one

way, and soldered.

Near the top, a bead was traditionally stepped out.

Sometimes this was only a thin stone shelf, which was

occasionally several graduated steps out, then back in.

Earlier, it was believed that this helped deflect wind

upward, but it was mostly for decoration. A bead is

sometimes an indication of the age of a chimney, as is

the mortar used. Wide, heavy beads were common in

the 1600s, then reappeared in Victorian houses.

Of course mud or clay, or even drystone, was tradi-

tional in the backcountry, but lime mortar was used

where available, and became more widely used after

the Civil War. Modern cement mortar wasn't evident

till around 1900 in the hills, about when the square

nails disappeared.

I usually finish the outside work on a fireplace, then

work the inside stone, mantel, heat-box ducts (if any),

and hearth. Again, I like for the logs to be pretty well

settled before I lay stone against them, inside or out.

Fireplaces take lots of time. You may contract yours

out or even build your house without one and add it

on later. Allow most of a summer if you do the job

yourself, unless you know your masonry. I know a

number of masons who regularly build a fireplace and

chimney in a week. I don't. I like for each day's stone-

work to be thoroughly set up and cured before I pile

the next thousand pounds or so of stone on. I aim for

two or three vertical feet a day, with several days

between, but you'll have lots of other things to keep

yourself busy while this job is going on.

These drawings show both the stepped and sloped chimney shoul-

ders, which are traditional above the fireplace. East Coast chimneys

normally incorporated an upstairs fireplace, so this shoulder was at

gable height.

Using the come-along to lift a large stone. The roof cutout will be

flashed where the chimney goes through.