Civil Engineering Reference

In-Depth Information

damper, if any, will go. Dampers are useful to shut out

the cold when there's no fire. If you buy a premade

damper, shape this firebrick box to it. Remember to

leave a a-inch space at the edges of the metal for heat

expansion. Lay the firebrick with mortar that has fire-

clay in it (about half the lime content).

Above the damper, drop back clear to the back,

leaving a smoke shelf to prevent downward gusts.

Above this, narrow the chimney front to back and side

to side to about 12 inches square for a 36-inch fire-

place and go for the sky, lining with clay flue tile. Set

the tile on this narrowed pyramid. The smokeless-

room theory works a lot like the venturi in a carbure-

tor, constricting the smoke flow at the damper, front

passage, then opening out. Downdrafts reach the

belled-out space above the smoke shelf and lose their

sense of direction. Heat rising overcomes the reduced

downflow here.

Line the inside of your fireplace cavity with fire-

brick, an expensive but durable substance that keeps

annoying bits of hot stone from popping off and rico-

cheting around the room. Bare stone will also crack

completely apart in a raging fire, so don't take the

chance. There's a special cement, called refractory

cement, for bonding this brick. (Or you can mix fire-

clay into the mortar.) I build the firebrick shape either

first or as I lay the stone, using corrugated masonry

ties to hold brick to stone.

The smoke shelf chamber should rise from the fire-

brick box and a steel brace across the front (leave

expansion room) to step in and accommodate the flue

tile. You can use brick here, parged inside with mor-

tar with fireclay mixed in. Concrete bricks also work

well here. Either way, be sure to leave room for the

damper to function properly.

The lintel stone should, of course, come down

below the top of the sloped or curved back so smoke

will be more inclined to lift off. Otherwise, it will roll

out into the room. This stone should be set on piers

built up even with or inside the walls. I break the

inside stonework out into the room from six inches to

a foot, enclosing the log ends. Building codes some-

times require you to keep two inches away from the

log ends here, so you have to do a vertical chinking

joint over wire lath to fill the space or scribe a trim

board to the stone and logs.

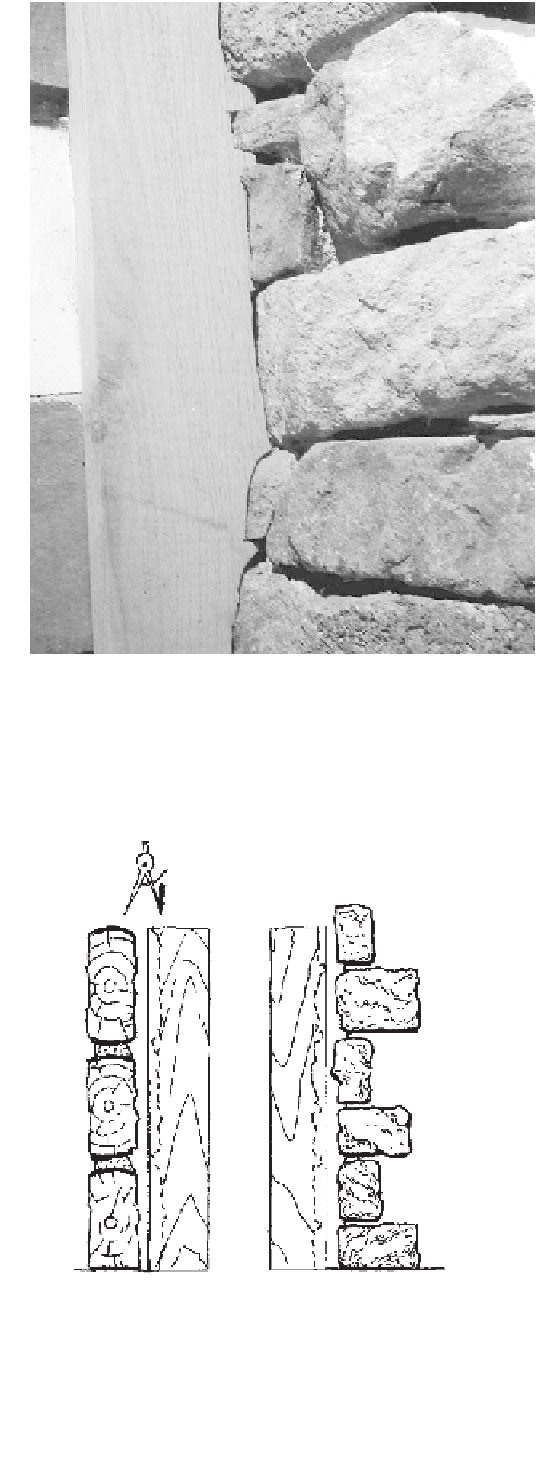

Logs and stones are irregular building materials, and joining them

requires ingenuity. Trim boards and drywall need to be scribed to

the logs or stones. Here mason Eric Bolton did an excellent job

scribing a trim board to his fireplace.

A good way to make scribe marks is to use a common compass.

Run the tool along the rough surface and mark the board. You can

then cut and trim and rasp the edge to fit the irregular surface.