Civil Engineering Reference

In-Depth Information

laid a plywood floor over that, fastening with short

drywall screws to the paneling. Then we carpeted the

strengthened ceiling/floor. (The subfloor was actually

on top here.)

It's a bit difficult to finish off flooring at the log walls

with molding, but if you smooth the worst humps out

of the logs at floor level, you can get a strip of quarter-

round to fit tight, with perhaps some caulking behind

it. We scribe the last flooring board carefully and don't

use any molding. We do use clear caulk.

An addition to our Missouri lean-to — containing

a small office and the baby's room — was floored with

recycled oak flooring, which we obtained for free. It

was laid over a subfloor of rough-sawn oak on oak

joists. Recycled flooring requires lots of sanding

because the pieces aren't in their original wear pat-

terns, and you get high and low spots against each

other. But it has a glow unlike new wood flooring.

Our current house additions have beam joists with

subfloor and remilled heart pine flooring. It's easier to

concentrate plumbing in these more conventionally

floored sections.

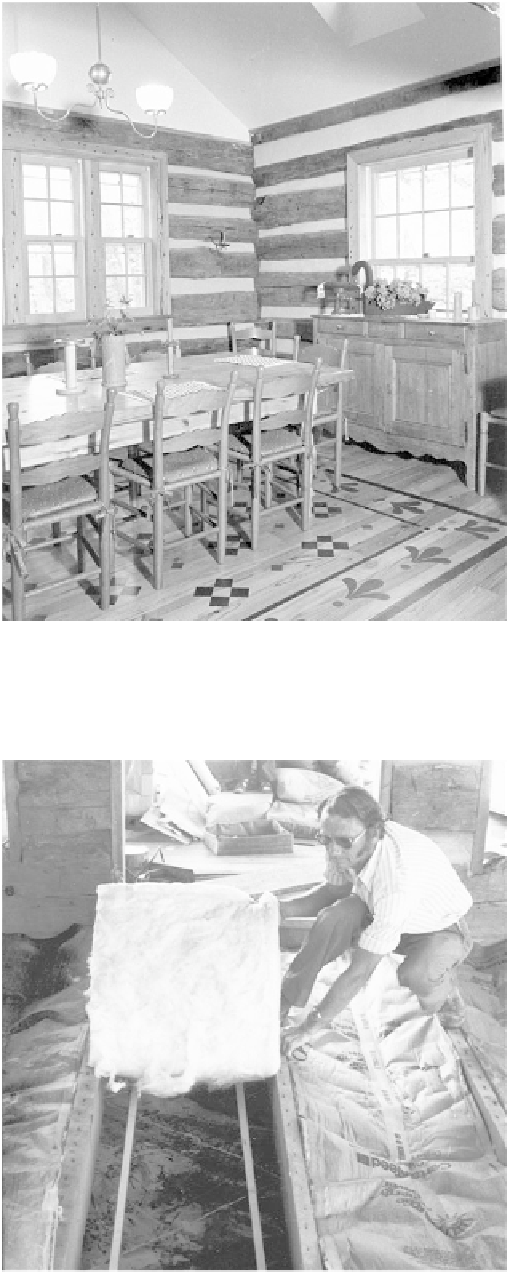

This antique, recycled heart pine floor was laid and sanded in the usual

manner. The owner engaged a friend to create a stenciled design to dis-

tinguish the dining area from the rest of the house and to match the

shape of the custom-built table.

Slab Floors

In recent years, concrete slab floors have been used in

log houses, and have been added to restored older cab-

ins. Sometimes this is painted with masonry paint;

sometimes it is left bare, to be covered here and there

with rugs. Sometimes floor tile is used over it. A slab

floor must always be vapor-sealed beneath to stop

moisture from coming up. It also means a raised foun-

dation, visible inside beneath the first logs or the wood

is too close to the ground. Too often, the concrete is

poured right against the logs with no vapor barrier,

and that rots the logs.

In one restoration, the owner decided to use a low-

ceilinged basement as an “English basement” (kitchen

and eating area in basement). The floor needed to be

lowered by at least eight inches. The only problem was

that this 600-square-foot basement floor was a six-

inch concrete slab. We had to jackhammer it out for

days. Cleanup was almost as much work as the tear-

out. Then, we dug down and graveled the full base-

ment. A new slab was wired and poured, becoming the

base for vinyl flooring.

Dan McRaven lays insulation between floor joists. We often tack

chicken wire or other mesh to keep the insulation from sagging.

Some builders use wire “tiger teeth” bent up into the joist space.

However, metal screening is more effective and more stable.