Civil Engineering Reference

In-Depth Information

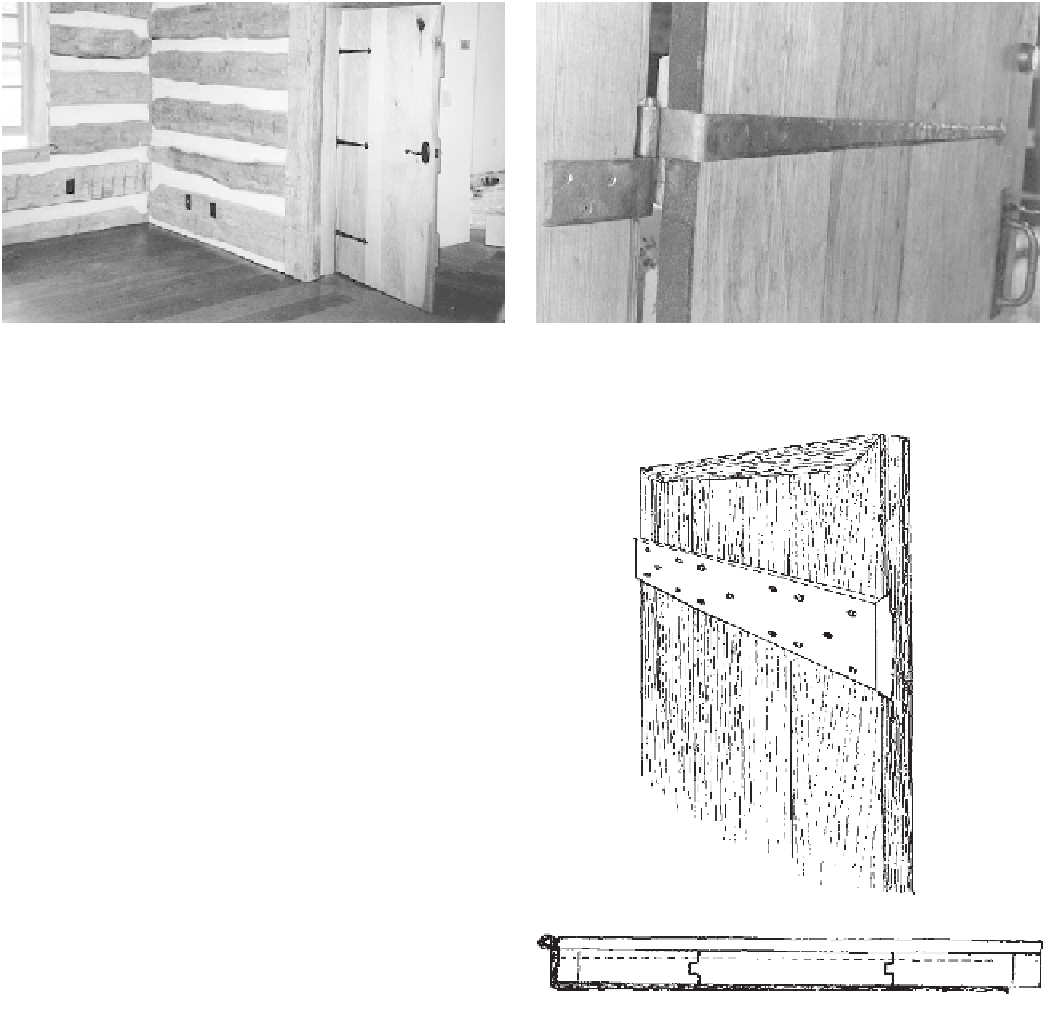

The short basement door was hand built, but the commercial hinges

and latch fit the design well.

Hand-forged hinge showing pin.

of these are bevel-cut to fit the dovetail cutouts, and

driven in from the side. Then forged nails are used in

an X-pattern in each board to secure the battens. The

door can't sag, and is more craftsmanlike than the

Z-pattern.

I use heavy glass in outside doors, finding safety

glass little more expensive and much safer than

double-strength. Also, building codes require it. Using

the router, I rabbet the window frame, caulk, lay in the

glass, then set a thin wood strip against it with small

screws. You can also use two strips with the glass

between. Always build the door rigid in some way to

keep stress off the glass.

I close the doors against felt-lined strips, as I do the

casement windows. At the sill, I use a flexible weather

stripping, which makes a stepped-up threshold

unnecessary, although certainly an option.

A stable wood, such as white pine, is good for doors;

yellow pine tends to warp. White oak is good, but heavy.

My favorite doors were for the Page Meadows

house in Virginia, of 1h-inch chestnut, dovetail cross-

battened and hung with forged hinges. These doors

were grooved and splined. We hand-planed for

texture.

Outside doors must be sealed to keep out moisture.

Oil the inside, too, to avoid cupping and warping. I

like tung oil, reapplied every four years or so.

The larger and later houses used commercially

milled doors, inside and out, available generally for

the past 150 years. They were usually pretty thin, and

have never seemed to fit the solid look or concept of

the overall log house.

The cabin door we build most frequently is this one of vertical boards

with the cross battens let in with a dovetail router bit. The battens are

cut at an angle and driven tightly from the side to hold the door rigid.

We always use it with forged strap hinges offset so the door swings in.