Civil Engineering Reference

In-Depth Information

time as estimating the angle, then adjusting after the

first trial, which you usually have to do anyway.

The same angle isn't really essential. A friend who

helped me with one cabin always worked the chamfer

about where he thought it should be, then used an

adjustable T-bevel to take the same angle to the next

notch. I do it all by eye.

I use a crosscut saw to make the vertical cut, but my

brother John, who has a steadier hand, likes the chain

saw. Remember to allow for the wide cut the chain

makes. Then we both use an axe or adze on the angle

cuts. You may not want to risk these long-handled

tools while perched up in the sky, which is where we

usually work the chamfers. A large chisel will do

nicely, but if you axe things, I suggest steel-toed boots.

You will almost certainly cut out too much wood

eventually, so go light till you get the hang of it. Too

wide a chinking gap means cutting the notch or cham-

fer deeper. Don't do this unless you need a wide gap to

keep the log level. More about that later.

If you do take out too much, and the log lies against

the one under it without closing the notch, you can

hew away part of the bottom edge or the top of the one

under it. Or save this log for later use. Or, you can slip

a piece of board into the notch as a spacer. This is not

done in the best craftsmen's families, I realize, but it's

sometimes necessary when restoring a house that has

parts of the notches split off.

In notching, keep an eye on the other corner, so that

your logs will be the same height as you work your way

up. You'll span the opening at its top, and this span-

ner log should be reasonably level. So measure each

corner, from the sill up, each course or so. Stay within

a couple of inches.

Some years back an aspiring log builder I knew got

the job of putting up a house I had consulted on. I vis-

ited the site one day to discover that he'd built an addi-

tion log wall, not paying attention to the relative

heights of the logs on each side of a doorway.

This man was a huge, high-energy individual whose

approach to building reminded me of a charging bull.

If a dovetail notch wasn't a tight fit, he'd take swipes

through it with a giant chain saw that resembled a

locomotive until it was different.

I pointed out to him that, at the top, his spanner

log wasn't going to span because one side of the door

was a foot higher than the other. He'd “adjusted” too

many notches on one side and that let the wall down.

He caught on fast. With a swipe of a mighty paw, he

sent log sections flying, and without a pause began

carving out replacements with that saw — which takes

us to keeping the whole thing level. Only theorists

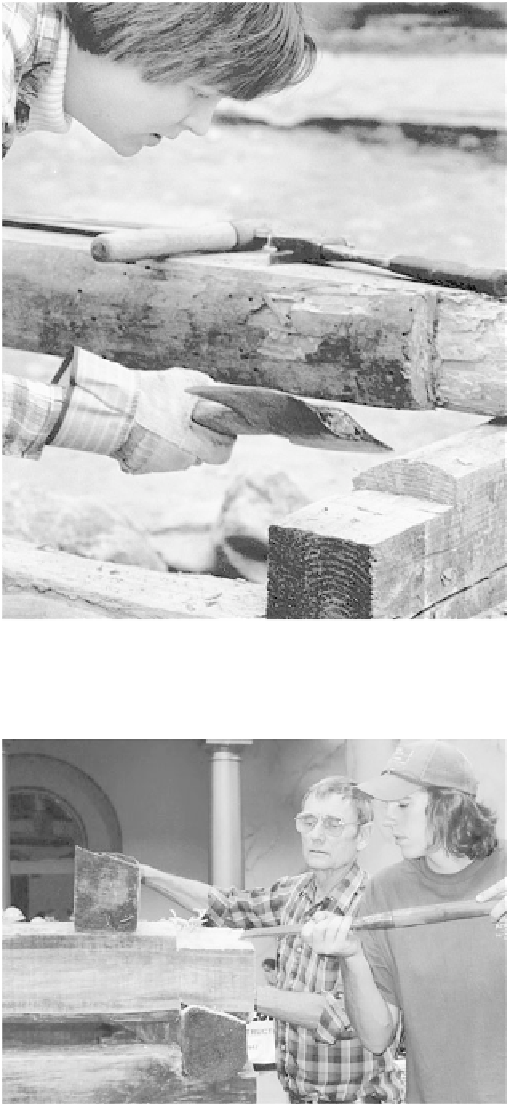

This is a square notch on an 1890s cabin log. Square notches were

used in later cabin construction, but did not provide the interlocking

advantages of the dovetail.

Willie Lehmann uses the slick to smooth a half-dovetail notch for a

better log fit. The slick is pushed with a side motion to slice the wood.