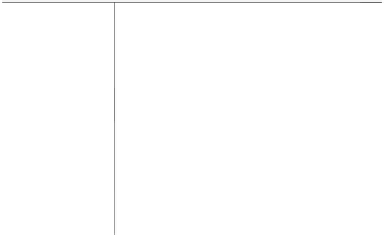

Chemistry Reference

In-Depth Information

Owner's Site

Vendor's

Site

Functional testing/verification

Owner's Site

Calibration

and

maintenance

Qualification

Structurally

validated

products

Installation

Operational

Performance

DQ

IQ

OQ

PQ

PQ

Prior to

purchase

of a new

type of

instrument

At

installation

(new, old, or

existing

unqualified

instrument)

After

installation

or major

repair of

each

instrument

Periodically

at specified

intervals for

each

instrument

After use

Before

Purchase

Before Use

System Suitability During Use

After Use

FIgure 2.1

A timeline approach to AIQ.

2.3.3 o

PerAtIonAl

Q

uAlIfIcAtIon

(oQ)

Once the IQ phase is completed, testing is done to verify that the instrument or

instrument modules operate as intended in an OQ phase, as illustrated in Figure 2.1.

First, fixed parameters, for example, length, weight, height, voltage inputs, pressures,

etc., are either verified or measured against vendor-supplied specifications. Since

these parameters do not change over the lifetime of the instrument, they are usually

measured just once. Next, secure data handling is verified. Finally, instrument func-

tion tests are undertaken to verify that the instrument (or instrument modules) meets

vendor and user specifications.

Instrument function tests should measure important instrument parameters

according to the instrument's intended use and environment. In HPLC, the follow-

ing types of tests might be included

• Pump low rate accuracy

• Gradient accuracy

• Injector accuracy

• Column oven and auto sampler temperature

• Detector wavelength accuracy and linearity

• Detector linearity

The analyst would first verify that all the individual modules in the system per-

formed the start-up diagnostic routines successfully, and then each module is tested

individually against predetermined specifications. Relevant OQ tests for each of the