Environmental Engineering Reference

In-Depth Information

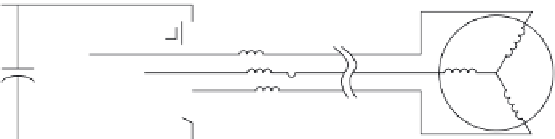

A power electronics controller is desired to interface the motor generator

to the system. This controller has two main functions. It must electrically

drive the motor during pumping operation. This involves inverting the DC

voltage using a pulse width-modulated, six-step, trapezoidal or other motor

drive strategy to control a three-phase power electronics-based inverter. The

impedance and voltage drop in the long lines between the inverter and the

motor (located near the bottom of the well) must be taken into account. This

inverter could be designed to drive the motor at only a single speed (sim-

pler implementation) or at variable speeds. A variable speed drive has the

ability to use lower power input (such as when the solar or wind source is

minimal), thus increasing the efficiency of the pumping cycle. Additionally,

it is possible to further optimize the pumping cycle by matching the photo-

voltaic solar voltage and current to the pump characteristic using a method

such as maximum power point tracking (MPPT).

12

The controller must excite the motor generator and rectify the output. Two

methods of exciting the generator were discussed earlier. It is recommended

here to employ the scheme involving advanced control of the power electron-

ics switches to simultaneously excite the machine and rectify the output. The

excitation capacitors are eliminated, reducing cost and increasing reliability.

Figure 4.10 is a schematic of the proposed unit, utilizing position feedback

sensed directly from the machine shaft.

A filter must be employed between the induction machine and the inverter.

This filter attenuates the voltage spikes that occur on the lines due to their

long length. A DC link capacitor is connected to stiffen the DC bus and

improve transient performance.

The function of the grid tie inverter/rectifier is twofold. It is intended to

operate as a commercial grid tie inverter to convert the DC power into 60 Hz,

AC grid-compatible power. In addition, the unit must step up and rectify

incoming AC power to DC power to supply the motor drive controller.

Induction

Machine

+

Filter

600 Vdc

-

Controller

Position Encoder Single

Commands from

system controller

FIGURE 4.10

Motor control inverter/rectifier.