Environmental Engineering Reference

In-Depth Information

of power generation. These parameters will be determined by both site char-

acteristics and the end use requirements.

Performance Modeling

The most important parameters for optimization in the design of this system

are the well hydraulic head, flow capacity, and electrical system efficiency.

Contrary to common well flow yield measurements, the parameter of inter-

est here is the measured flow that can be re-injected into the aquifer, not

the flow that can be pumped out or “yielded.” While aquifer re-injection is

accomplished at various projects across the country, methods to accurately

determine re-injection flow capacity are more complicated than the common

pumping calculations. This section will provide simplified models to predict

the re-injection flow of a well with a given hydraulic head. It will also analyze

the allocation of hydraulic head between the head that powers the turbine

and the head that re-injects water into the aquifer. Also addressed are the

electrical system performance and efficiency during electricity generation.

The initial thought of a designer of this type of system is to approximate

the re-injection flow capacity as roughly the same as the yield capacity of

a well. Let us test this assumption for steady state flow conditions. When

drawing water from a well, a cone of depression is created around the well

because of the finite transmissivity of the aquifer material. This cone can

depress down to the point at which the pump is located and no further.

Thus, the well yield is limited by the hydraulic conductivity of the material

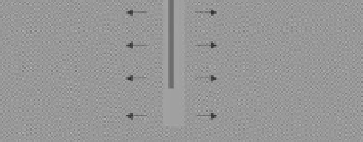

and the location of the pump in the well. The right half of Figure 4.4 depicts

two-dimensional effect of the cone of depression that occurs when water is

drawn from a well.

HEAD

Turbine

Turbine

Pump

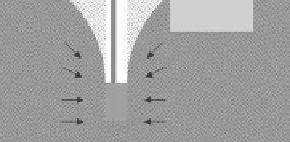

Mound of

Injection

HEAD

Injection

Static Water Level (datum)

Cone of

Depression

FIGURE 4.4

Mound of injection and cone of depression.