Geoscience Reference

In-Depth Information

point-counting for air void analysis, alternative image

analysis techniques are being developed in an effort to

make modal analysis more efficient. From the volume

data, the original mix proportions (by weight) can be

calculated in a number of different ways. One approach

is detailed in Concrete Society TR No. 32 (1989) and

reproduced in St John

et al

. (1998).

Modal analysis is a suitable alternative to chemical

analysis methods for determining cement content and

aggregate grading, such BS 1881: Part 124 (British

Standards Institution, 1988). Modal analysis may be

preferable in circumstances where chemical analysis may

be subject to inaccuracies from the presence of acid-

soluble aggregate constituents (limestone etc.) or

chemically altered concrete (leaching and other

deleterious reactions). Experience to date suggests that

binder content determinations by modal analysis are of

comparable accuracy (or better) to chemical analysis

(Concrete Society, 1989).

particles at the upper surface. Trafficking in service had

caused the aggregate particles to collapse into the voids

giving the appearance of pop-outs at the surface.

The concrete ingredients must be adequately mixed

and unsegregated to ensure a uniform product. After

placing there is a tendency for the concrete to segregate

while in the plastic state, especially in poor-quality mixes

lacking cohesion. Workmanship factors, such as allowing

fresh concrete to flow along a form or excessive vibration,

will exacerbate segregation. Segregation manifests itself

in two main ways, which can both be identified and

assessed by petrographic examination. The first consists

of separation of coarse aggregate towards the bottom of

the form, which can be detected in core samples (

189

).

The second, which is characteristic of wet mixes, is the

bleeding of mix water (and cement grout) to the surface.

Bleeding can result in the formation of less durable,

highly microporous zones and bleeding channels.

Bleeding channels are readily observed in thin section

using fluorescence microscopy, owing to their tortuous

course (

190

) and associated enhanced microporosity (see

197

). An external manifestation of bleeding is the

deposition of a cement-rich laitance layer on the concrete

surface. As the laitance typically has a very high W/C, it

is porous, soft, and weak. When excessive laitance is

present on a concrete floor slab or pavement surface, it

may consequently be prone to dusting.

Adequate curing and finishing are crucial to the

production of durable concrete. The objectives of curing

are to prevent the loss of moisture and to control the

temperature of concrete for a period, to achieve the

W

ORKMANSHIP

General concrete workmanship issues that can be

assessed by petrographic examination include

compliance with specified mix proportions, the adequacy

of mixing, and effectiveness of placing, compaction,

curing, and finishing. A variety of specific workmanship

issues may need to be investigated as the result of a

perceived inadequacy of the finished concrete product.

For example, insufficient strength and durability

resulting from extra water being added to the mix at the

site can be checked for by assessing the W/C, using

fluorescence microscopy.

Although not a normal part of quality control of

concrete construction, it may become necessary to check

that the concrete ingredients and their mix proportions are

as specified. Such a requirement may arise if suspicions

have been raised regarding an unauthorized change of

materials, or from unsatisfactory concrete appearance or

performance. Petrographic examination can be used to

establish the type/source of the ingredients and the mix

proportions can be checked by modal analysis.

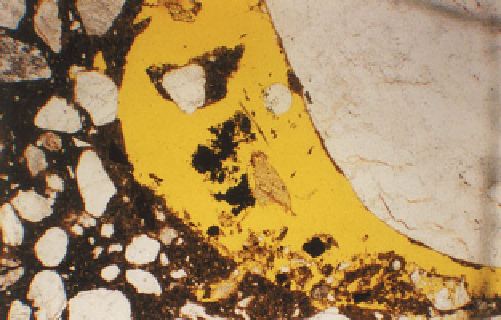

Once fresh concrete is placed, it is typically compacted

(by vibration) to eliminate entrapped air bubbles. This is

important as there is an inverse relationship between the

porosity and strength of concrete and the presence of

entrapped voids will reduce strength. The characteristics

of air voids and the assessment of compaction have been

discussed on p. 92. Durability issues can arise from air

voids that form beneath reinforcement bars or coarse

aggregate particles (as entrapped air voids or water

voids). Figure

188

shows a case of a concrete floor slab

where air voids had formed below coarse aggregate

188

188

Large air void (yellow) beneath a quartzite coarse

aggregate particle (white) that was the cause of

apparent 'pop-outs' on a concrete floor slab; PPT,

×35.