Geoscience Reference

In-Depth Information

compaction can be described thus:

Excess voidage, %

with air void determination, this is performed on finely

ground concrete slice specimens (see

184

) that must be

large enough to represent adequately the concrete

element from which it is taken (typically 100 × 100 mm

minimum area). The normal methods involve either

linear traverse or point-counting determinations to

establish the volume proportions of coarse aggregate,

fine aggregate, cement paste, and air voids. As with

Compaction

>0.5

Very good

>0.5-3.0

Good (normal for satisfactory

quality structural concrete)

>3.0-5.0

Medium

>5.0-10.0

Poor

>10.0

Very poor

In addition, the term 'honeycombed' is used to describe

interconnecting large entrapped air voids (excess voidage

may be as high as 30% locally) arising from inadequate

concrete compaction or a lack of mortar (binder and fine

aggregate).

For accurate determination of the air void system, it is

necessary to undertake manual point-counting or linear

traverse measurements of finely ground concrete slice

specimens. In Europe, determination of air void content

of hardened concrete is performed in accordance with EN

480: Part 11 (British Standards Institution, 2005) and in

America, ASTM C457 (ASTM International, 2008c) is

used. It is important to ensure that the sample is

adequately representative of the concrete. The minimum

area of concrete slice for concrete with a 20 mm coarse

aggregate would be 10,000 mm

2

(and greater for concrete

with larger aggregate). The finely ground slice specimen

is carefully prepared, ensuring a scratch-free surface with

well defined air void edges. The volume proportions of

aggregate, cement matrix, entrapped air voids, and

entrained air voids are determined by examining the slice

using a low-power binocular microscope with the aid of

an oblique incident light source and a mechanical stage.

The air void content is then calculated using formulae

supplied in the EN or ASTM standards.

The manual method of air void analysis takes several

hours to perform for each specimen. With this in mind,

an automated apparatus, the RapidAir 457 has been

developed to perform ASTM C457 or EN 480-11 air void

analysis in less than 15 minutes (Jakobsen

et al

., 2005).

The apparatus comprises a computerized control unit

(and monitor) with image analysis software, a video

camera, and a microscope objective mounted on a

moving stage (

186

). The concrete sample preparation for

image analysis is similar to that required for the manual

method, except that the contrast between the air voids

and the concrete has to be enhanced by colouring (

187

).

186

186

The RapidAir 457, Automated Air Void Analyzer

system. (Courtesy of Concrete Experts International.)

187

187

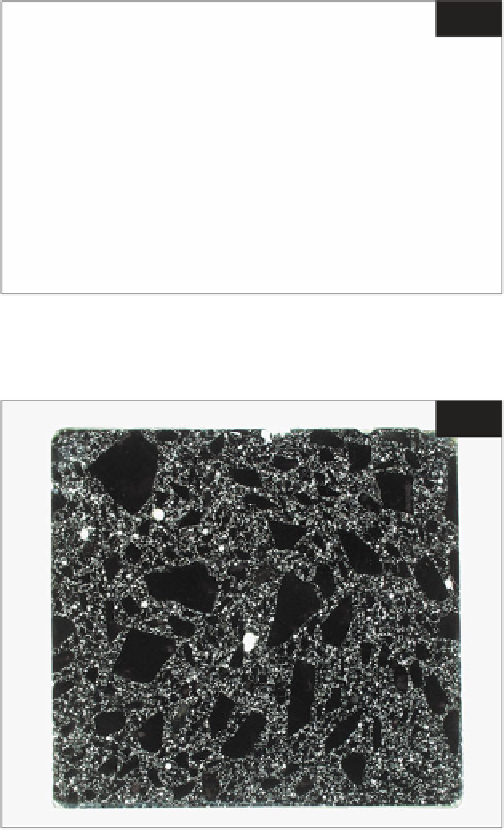

Surface of an approximately 100 × 100 mm finely

ground slice of air-entrained concrete after contrast

enhancement, to allow air void analysis using the

RapidAir 457. Entrapped and entrained air voids

appear white against the black background of

aggregate and cement matrix. (Courtesy of Concrete

Experts International.)

M

ODAL ANALYSIS OF CONCRETE BY PETROGRAPHIC

PROCEDURES

Modal analysis of hardened concrete (also known as

'micrometric' analysis) may be used to determine binder

content, aggregate content, and aggregate grading. As