Geoscience Reference

In-Depth Information

most likely cause of internal sulfate attack is the use of

sulfate- or sulfide-contaminated aggregates. These may

release sulfate ions within the concrete that may react

with the cement matrix to form ettringite and/or gypsum

as described on p. 102. Although less common, internal

sulfate attack can result from cement or mixing water

with high sulfate contents. In thin section, the

appearance of concrete suffering from internal sulfate

attack includes the occurence of a network of cement

matrix cracks, that along with air voids, are filled with

secondary deposits of ettringite or gypsum. Unlike

external sulfate attack, evidence of deterioration will not

be confined to the surfaces.

Internal sulfate attack is responsible for 'the mundic

problem' in southwest England. Here, the expansive

cracking of concrete blocks and mass concrete has been

caused by the use of mining waste aggregate containing

pyrite (FeS

2

). The mechanisms of deterioration involve

oxidation of the pyrite (Bromley & Sibbick, 1999).

Consequently the equity value and resale potential of

many, mainly pre-1950s domestic properties have been

adversely affected by uncertainties about the nature of the

concrete used in their original construction. A

petrography-based sampling and testing procedure

(described in Stimson, 1997) was therefore adopted to

determine if buildings contained concrete with potentially

expansive aggregate (and the likely risk of future

deterioration). The procedure involves taking

representative core samples (50 mm diameter) from the

concrete elements of the building and examining them in

hand specimen using a low-power microscope (and in thin

section if uncertainties arise). This screens for evidence of

deterioration and is used to classify the aggregate

lithologies present into either Group 1 (inert) or Group 2

(potentially deleterious). A detailed atlas of concrete

aggregates used in southwest England has been collated by

Bromley (2002). Figure

208

shows concrete blocks made

with china clay waste, which is a commonly seen Group

1 aggregate. Figure

209

shows concrete made with

potentially deleterious crushed metasedimentary mining

waste aggregate, which is classified as Group 2. Providing

that the concrete appears sound and contains less than

30% of Group 2 aggregate then the property is likely to be

considered safe for mortgage purposes by lenders. Since its

introduction, the petrographic assessment procedure has

enabled approximately 80% of previously blighted houses

in southwest England to be saleable again.

Delayed ettringite formation (DEF) is a rare but

potentially severe form of internal sulfate attack of concrete

(Quillin, 2001). A certain amount of ettringite (hydrous

calcium sulfoaluminate) forms as part of the normal

cement hydration products. However, if the concrete is

subjected to elevated temperatures during curing (>65°C)

this ettringite formation may be 'delayed' and if the

hardened concrete is subsequently exposed to moisture, the

ettringite may re-form causing expansion and cracking,

months or years after construction. Concrete may be

exposed to high temperatures during curing as a result of

208

209

208

Concrete block from southwest England

containing Group 1/1 china clay waste aggregate,

consisting chiefly of quartz (grey), with minor feldspar

(grey), muscovite mica (brightly coloured), and

tourmaline (orange). The uncarbonated cement matrix

appears black; XPT, ×35.

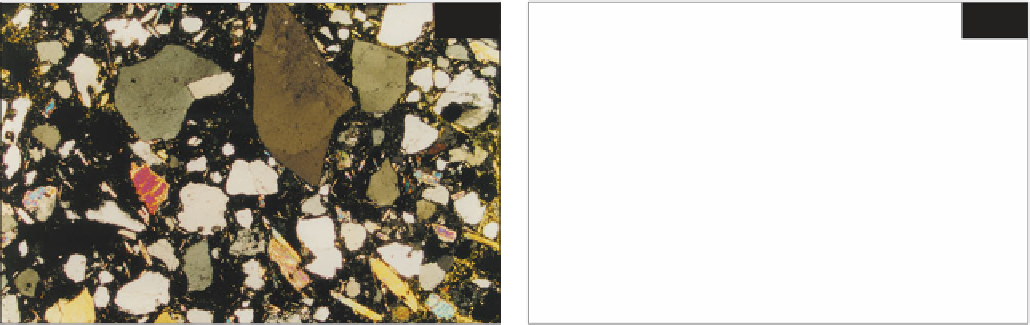

209

Concrete block from southwest England containing

Group 2/1 crushed phyllite ('killas') aggregate. The

aggregate particles are coated by iron oxide (dark red)

and the cement matrix is cracked (yellow) suggesting

deterioration due to pyrite oxidation. The carbonated

cement matrix appears brown; XPT, ×35.