Civil Engineering Reference

In-Depth Information

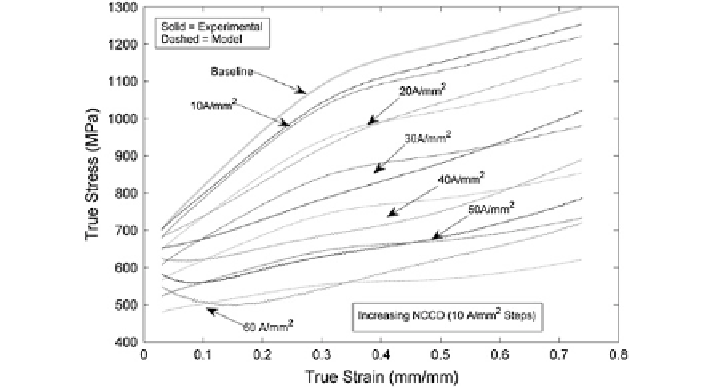

Non-constant current density (NCCD) testing that mapped the material flow stress

for EAF. The model is shown in Eq. (

4.11

).

σ

predicted

=

K

′

ε

n

ε

m

exp

−(ε −

c

)

B

A

(4.11)

where

σ

predicted

is the predicted flow stress with the application of electricity,

K

′ is

the strength coefficient,

ε

is the strain,

n

is the strain hardening exponent,

ε

is the

strain rate,

m

is the strain rate sensitivity exponent,

is the current density, and

A

,

B

, and

C

are material specific constants for this model.

Using this model, the NCCD tests were fit using the stress predictor equation

to examine the relationship for 304 Stainless Steel and Grade 5 titanium. The

material specific constants were determined using least squares regression and

are shown in Table

4.4

. The corresponding results for the 304 Stainless Steel and

Grade 5 titanium are shown in Figs.

4.26

and

4.27

, respectively. As shown, the

model was fairly accurate at predicting the flow stress behavior for both materi-

als. On average, the stainless steel experimental flow stress curves were averaged

or approximated using this flow stress predictor. When considering titanium, the

large reductions that were seen at higher current densities were fairly approxi-

mated, however, from a possible threshold effect that causes a non-linear increase

in the flow stress reductions, the lower current density curves suffered in predict-

ability and were underestimated.

Table 4.4

NCCD model

constants

A

B

C

1.39

0.007869

−

0.1385

SS304

−

6

7.95

×

10

G5 titanium

3.83

0.00234

Fig. 4.26

SS304 NCCD empirical modeling