Civil Engineering Reference

In-Depth Information

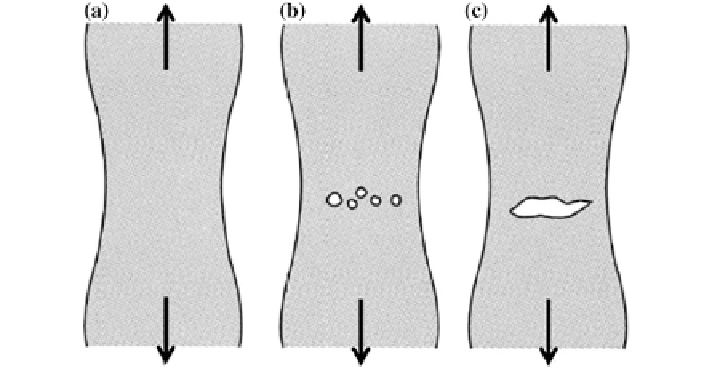

Fig. 3.10

Ductile fracture stages.

a

Initial Necked Region.

b

Formation of Micro-Voids.

c

Coalescence to Larger Void

stress induces separation of the material at grain boundaries or at small impurity

particles (Fig.

3.10

b). As the local stress in the material increases, the micro-voids

grow and coalesce into larger voids (Fig.

3.10

c). Over time, crack initiation begins

at the void and the crack grows till the material ultimately fractures.

The high stresses within the material that causes micro-voids to form can be

a result of pinned dislocations within the lattice. As a result of the applied cur-

rent providing energy to the dislocations, the added energy can allow for pinned or

stuck dislocations to continue moving again. Consequently, this reduces the local

stresses within the material's lattice and delays the process of void formation and

fracture. This theorized ability of the electric current to supply sufficient energy to

allow for pinned dislocations to be mobile can explain the observed effects seen in

experimental testing [

6

,

21

].

3.3.4 Supporting Experimental Results

There has been various experimental works performed, which support the new

electroplastic theory. Specifically, the experimental conclusions will discuss the

heating effects of applied electricity and will address the increased atomic-level

vibrations generated by the increase in temperature at lattice “hot spots.”

Heating and increased atomic-level vibrations

• Threshold versus resistivity relation [

22

]

• Dislocation density versus temperature relation (stationary-electrical tests) [

4

]

• Springback elimination in sheet bending [

23

]

• Dislocation density versus EEC (EAF tests) [

4

]