Civil Engineering Reference

In-Depth Information

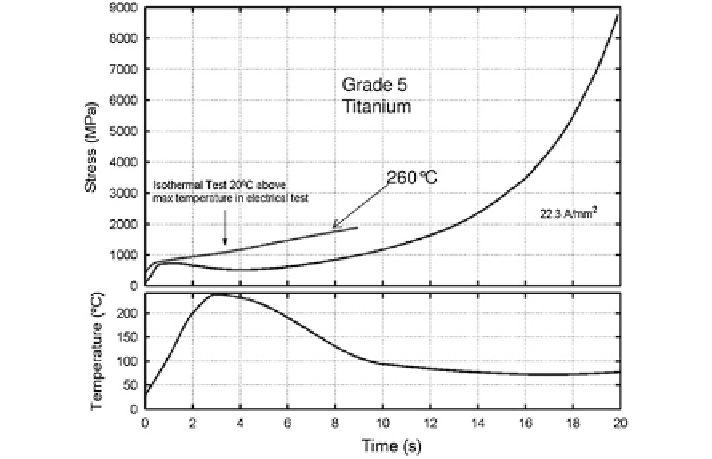

Fig. 2.6

Experimental EAF modeling [

37

]. A previous research work proved that the stress-

strain profiles for an EAF test, and an isothermal test run at the maximum temperature reached

during the EAF test, were considerably different. Additionally, this confirmed that the effects of

EAF were not solely contributable to resistive heating or thermal softening

transfer or thermodynamic phenomenon, or performing any mechanical modeling

[

35

]. The effects/relations of these inputs are described below:

• The thermal conductivity (

k

), density (

ρ

), specific heat (

C

p

), heat transfer coefficient

(

h

), and resistivity (

r

) all affect the heat transfer and ultimately the stress-strain

characteristics of the EAF process. Additionally, each of these variables change as a

function of temperature, so depending on the temperatures reached during an EAF

process, these variables could have weighted effects. These intrinsic properties are

not only important for the workpiece, but it is also critical to know these properties

for the forming dies as well.

• The strength coeficient (

C

) and strain hardening exponent (

n

) are intrinsic

properties that determine the magnitude and shape of the forming load profile

of an EAF test (and any forming test in general). Further, both are affected by

the temperature of the workpiece and forming dies in the process. Any type

of metal deformation modeling would need to include the effects of both the

strength coefficient and strain hardening exponent at a minimum.

• The initial grain structure (i.e., grain size, grain direction) of a material can affect

the heating and mechanical characteristics of a workpiece during EAF. The grain

size dictates how often moving dislocations must pass through grain boundaries

which cause dislocation pile-ups and can limit achievable deformation. In addi-

tion, the applied electrons must also pass through the grain boundaries and the

grain size (dictating the number of boundaries) will potentially cause the work-

piece to become hotter (more boundaries) or cooler (less boundaries).