Civil Engineering Reference

In-Depth Information

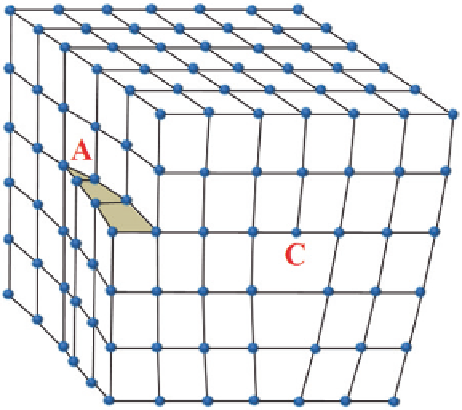

Fig. 1.8

Mixed dislocations.

Mixed dislocations are a

combination of edge and

screw dislocations

The third type of dislocation is the mixed dislocation, as shown in Fig.

1.8

.

Most of the dislocations in metals are mixed dislocations, since they may consist

of multiple lattice defects that are representative of both edge and screw disloca-

tions. In the figure, as the force is exerted at point A, the bonded atoms at the loca-

tion of where the force was applied break bonds with the aligned atoms and reform

bonds with the atoms one atomic spacing in the direction of the force to cause a

screw dislocation. This causes one set of bonded atoms in the top half of the unit

cell to now be un-bonded, which is shown by the edge dislocation at point C.

Regardless of the dislocation type, the number of dislocations within a metal

increases as the level of plastic deformation increases. This is because the disloca-

tions do not only move through the lattice, but new dislocations are created at lat-

tice defects. A dislocation line can be classified as an un-bonded string of atoms.

A defect in the lattice disrupts the equilibrium bonding of the lattice. If forces are

exerted on the lattice and bonds must consistently break and reform, this disruption

by the lattice defect can create bonding inconsistencies in the form of dislocations,

because of the extra energy needed to break and reform bonds around this defect.

There are certain “pathways” that dislocations can move throughout a metal's lat-

tice. These pathways are called slip systems. The dislocations travel on slip systems,

which are comprised of slip planes and directions, and are specific to the particular

crystalline structure of the material. While traveling on these slip systems, the dislo-

cation motion can be hindered by different interfacial defects within the lattice. Such

defects include impurities, voids, grain boundaries, faults, and other dislocations. As

these obstacles hinder the dislocation movement, the dislocations begin to pileup,

thus increasing the forces needed to continue plastic deformation. This phenomenon

is known as strain hardening. In order for the dislocations to be able to surpass the

obstacles, additional energy is required to force the dislocation past the defect. In

order for the dislocations to continue moving, there must be enough energy to: (1)