Civil Engineering Reference

In-Depth Information

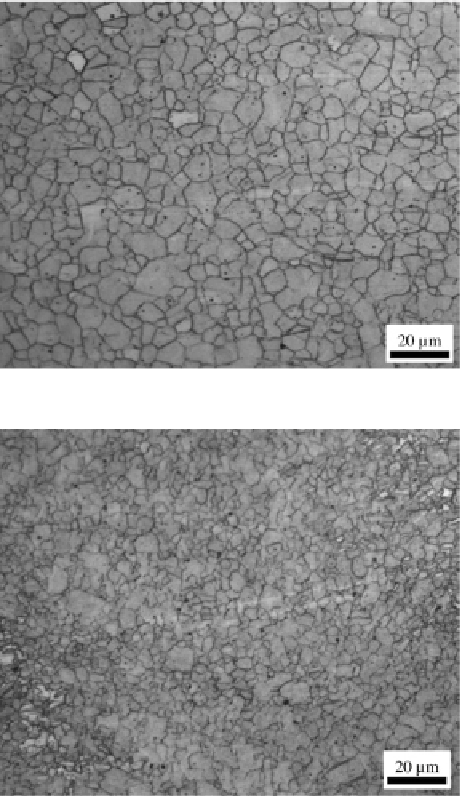

Fig. 8.27

Microstructure of

continuous EAF (150 A) test

(sample 12) in orientation

1 at L2

Fig. 8.28

Microstructure of

continuous EAF (150 A) test

(sample 11) in orientation

1 at L1

and strain response of the test is suggestive of dynamic recrystallization due to

the decreasing stress response after a peak stress is reached. This type of behavior

has been noted in works performing elevated temperature forming of magnesium

[

10

,

11

]. The difference is that the temperature rise is a result of Joule heating

within the material as compared to external heating in a chamber. Also, unlike

external heating methods, a temperature gradient is present along the length of the

specimen. Consequently, this allows for a variation in deformation behavior along

the specimen length which corresponds to the observed variation in microstruc-

ture. The localized deformation behavior is illustrated in Fig.

8.30

where there is

an extreme amount of localized deformation at L1. From a visual perspective, it

appears that L3 and L2 only have a small amount of deformation and the defor-

mation is concentrated at L1. Also, it appears that dynamic recrystallization has