Civil Engineering Reference

In-Depth Information

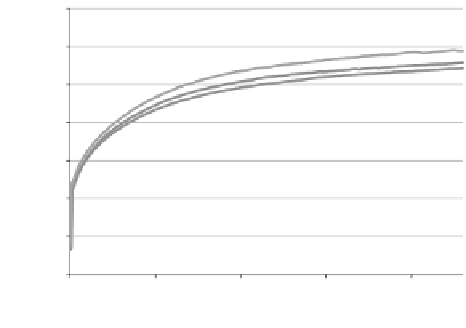

Fig. 8.2

Thermal profiles of

stationary electrical tests run

at CD

=

15 A/mm

2

[

5

]. There

was no significant difference

in the thermal profiles of

the stationary electrical tests

run on the different heat

treatments

350

27.20µm

15.08µm

21.99µm

300

250

200

150

100

50

0

0

5

10

15

20

Time (s)

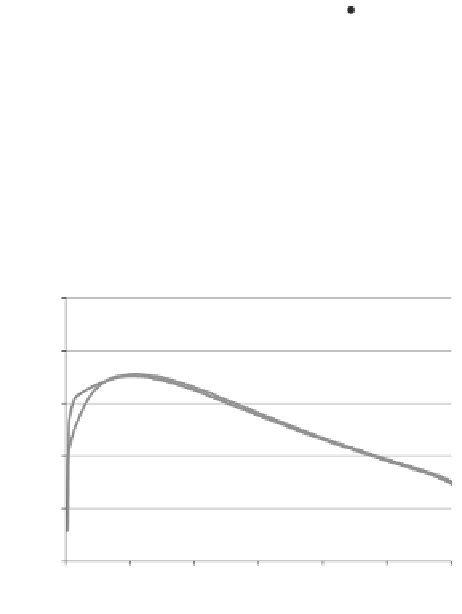

Fig. 8.3

Thermal profiles of

EAF tests run at CD

=

15 A/

mm

2

[

5

]. As was the case

with the stationary electrical

thermal profiles, there is no

significant difference in the

EAF thermal profiles as well

250

200

27.20µm

150

15.08µm, 21.99µm

100

50

0

0

5

10

15

20

25

30

Time (s)

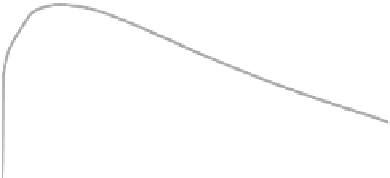

Fig. 8.4

True stress-strain

profiles for conventional

compression tests [

5

]. When

testing the different heat-

treated specimens under

conventional compression,

there was no difference in the

conventional compression

stress-strain profiles

1400

1200

1000

800

15.08 m, 21.99m,

and 27.20 m

µ

µ

µ

600

400

200

0

0

0.2

0.4

0.6

0.8

1

1.2

True Strain

Figure

8.4

displays the true stress-strain profiles of all the parts during a con-

ventional compression test at a deformation speed of 0.5 in/min. The stress-strain

curves are identical, regardless of the grain size.