Civil Engineering Reference

In-Depth Information

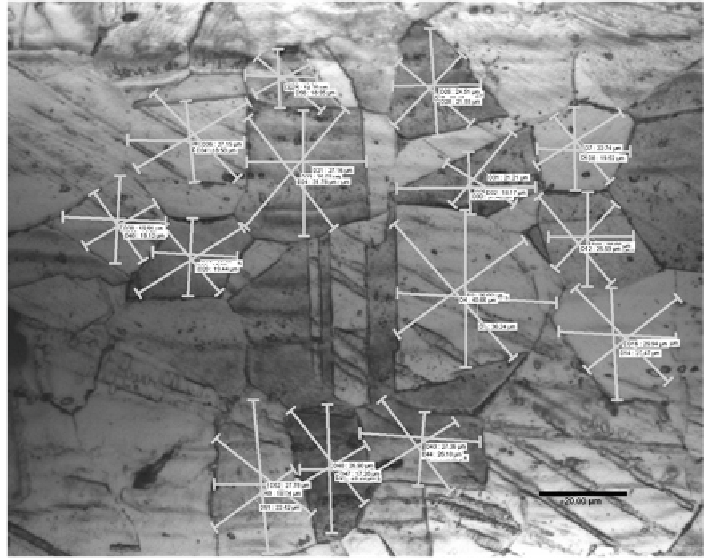

Fig. 8.1

Example of the four-measurement method for determining the average grain size [

5

].

Each complete grain in the micrograph was measured at four different angles (0°, 45°, 90°, and

135°) to account for any differences in grain orientation

8.1.2 Experimental Grain Size Testing

The following results present the testing performed on the stainless steel sam-

ples with the different grain sizes produced from the heat treatments. Figure

8.2

shows the thermal profiles of stationary electrical tests run at a current density of

15 A/mm

2

at a static load of 2,700 N for the three parts. Two replicates were run

for each grain size, and the replicates were consistent for each respective grain

size. The figure shows that the largest grain size has a thermal profile consistently

higher than the other two grain sizes (about 15 °C hotter at the end of the test).

This is uncharacteristic, because it was expected that the specimen with the small-

est grain size would have the hottest temperature profile because there would be

more localized scattering at grain boundaries. However, the difference between the

three grain sizes is minimal.

Figure

8.3

shows the thermal profiles for EAF tests run at a starting current

density of 15 A/mm

2

and a deformation speed of 0.5 in/min. As was the case with

the stationary electrical tests in the prior figure, the specimens with the largest

grain size had the highest temperature response (again, about 15 °C hotter at its

maximum temperature).