Civil Engineering Reference

In-Depth Information

Mechanical Load

e

-

e

-

e

-

e

-

e

-

e

-

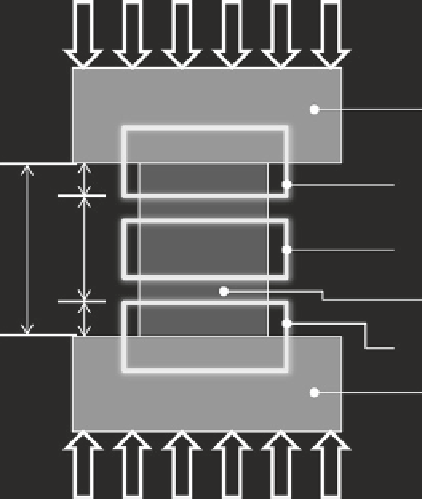

Top Die

L

c

Zone 1, R

1

L

Total

L

w

Zone 2, R

2

Workpiece

L

c

Zone 3, R

3

Bottom Die

e

-

e

-

e

-

e

-

e

-

e

-

Mechanical Load

Fig. 5.7

Die and workpiece zones [

13

]. The dies/workpiece were divided into three zones where the

top

and

bottom

zones

accounted for contact area/interface obstacles, while the

center zone

did not

• The workpiece and dies are divided into three zones, as shown in Fig.

5.7

, where:

- Zone 1 is equivalent to Zone 3.

- The real contact area

<

80 % of the apparent contact area for Zones 1 and 3

and has a length of

L

c

, which depends on the surface aspect (asperity peaks).

- The real contact area is equal to the apparent contact area in Zone 2.

• One voltage value is used in the thermal/mechanical calculations, but it is com-

prised of proportioned voltages from each zone (

V

z

1

,

V

z

2

, and

V

z

3

), as shown below.

The value used for

L

c

in Eq. (

5.22

) was 1.27 mm. This was about 20 % of the total

specimen height. This was an estimation based on the thermal videos, where exces-

sive heating was apparent at these locations when electricity was applied.

L

c

L

Total

L

w

L

Total

L

c

L

Total

V

Total

=

·

V

Z

1

+

·

V

Z

2

+

·

V

Z

3

(5.22)

Equation (

5.22

) is a simplified approach to the more complicated problem of

thermal contact resistance. In reality, Zones 1 and 3 are regions where the cur-

rent flow between the dies and specimen is constricted to the narrow intermetallic

contacts. A thermal contact resistance calculation should include the resistance of