Civil Engineering Reference

In-Depth Information

140

x10

3

120

60

r

˕

100

r=0,53d=3,2mm

80

60

Seale 8 x 19 - NFC - sZ

nominal diameter

40

d = 6 mm

R

2

= 1370/1770 N/mm

2

nominal strength

20

sheave diameter

D = 86 mm

tensile force

S = 2.25 kN

0

0

20

40

60

80

100

120

140

160

180

deflection angle

ˑ

D

0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

rope contact length / the rope lay length

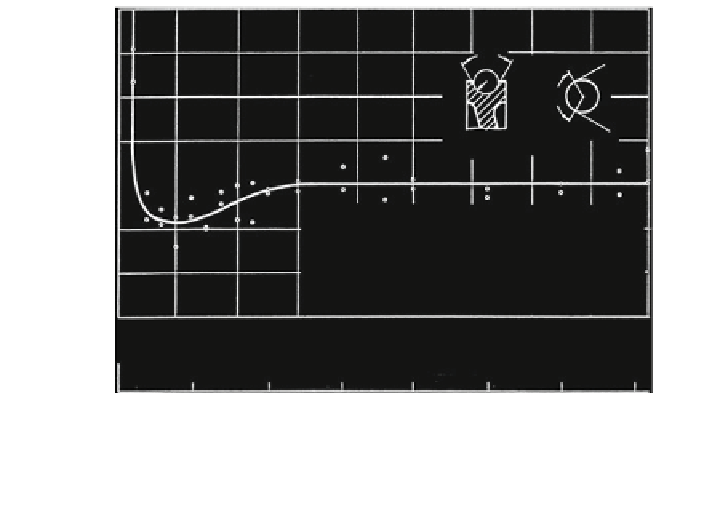

Fig. 3.53

Breaking number of bending cycles of a rope for different deflection angles, Müller

(

1961

)

3.2.3.9 Side Deflection of the Rope

It has been well-known for a long time that the side deflection of the rope from the

sheave groove reduces the number of rope bending cycles. Therefore the technical

rules prescribe the limits of 4 for the angle to be allowed for the stranded ropes

and 1.5 for non-rotating and low-rotating ropes.

Matthias (

1966

,

1970

) has described the contact form of a side-deflected wire

rope on the groove flank. The first systematic bending fatigue tests with a different

side deflection for the rope were carried out by Neumann (

1987

). Figure

3.54

shows as his results the discard number of bending cycles for side deflection angles

between

#

= w = 0 and 4.

Schönherr (

2005

) researched the influence of the side deflection on the breaking

number of bending cycles between the side deflection angle w = 0 and 7 in a

great number of bending fatigue tests. The tests were carried out on six ordinary

lay ropes and multi-strand ropes. The diameter ratio was D/d = 12.5 and 25 and

the specific tensile force varied between S/d

2

= 58-312 N

/

mm

2

. As an example,

Fig.

3.55

shows the breaking number of bending cycles N and N

10

of a multi-

strand rope, with the side deflection in the same (+ sign) or in the opposite (- sign)

direction to the lay direction of the outside strands. All the results show that the

groove opening angle between c = 30 and 60 has no influence on the number of

rope bending cycles.

Search WWH ::

Custom Search