Civil Engineering Reference

In-Depth Information

10

6

round groove

with unloading

multi-layer spooling

D/d =

25

20

10

5

40

10

4

25

20

10

3

10

1

10

2

specific tensile force S/d

2

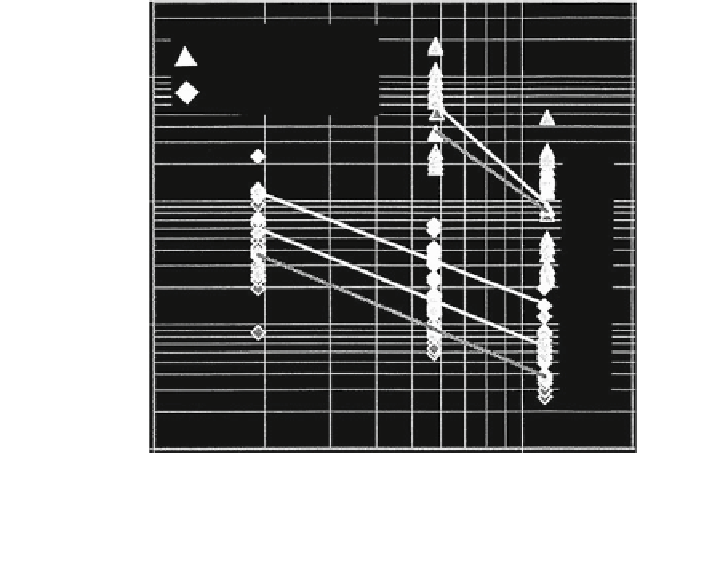

Fig. 3.52 Breaking number of rope bending cycles under multi-layer spooling and in steel

sheaves with round grooves r = 0.53d, Weiskopf et al. (

2005

)

is large and therefore the bending stress is small. A dip in the number of bending

cycles exists in this case at a deflection angle

#

D,dip

& 20. As is to be expected,

that corresponds to the deflection angle D

#

= 19.7 arising out of Häberle's

(

3.29

). The reason for this dip in rope endurance is that the line pressure—which

has been more or less concentrated on one point up to this angle—as reached its

maximum and the radius of the rope curvature reaches that of half of the sheave

diameter producing the full fluctuating bending stresses, see Sect.

3.1.6

. The

critical deflection angles from Müller's bending fatigue tests and Häberle's pres-

sure measurement tests are nearly the same, but it should be noted here that the

ropes used for the two groups of tests did not have the same construction.

For bigger deflection angles over about 60, the number of bending cycles is

more or less constant, Fig.

3.53

. On looking at the second abscissa in Fig.

3.53

, the

ratio of the rope contact length and the rope lay length, it is however imaginable

that there may be a slight influence on the number of bending cycles. Donandt

supposed such an influence to exist as Woernle (

1934

) reported. Jurk (

1973

) found

such an influence for this ratio which was only slight on the number of bending

cycles but great on the number of wire breaks.

Search WWH ::

Custom Search