Civil Engineering Reference

In-Depth Information

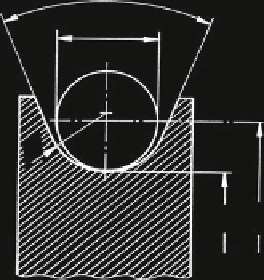

Fig. 3.33

Sheave with round

ʳ

groove

d

D

0

D

based on the actual or nominal values of a rope cross-section or rope diameter. For

detecting the influence of wire stresses, the real dimensions have to be used. How-

ever, for practical endurance tests, test results related to the nominal rope cross-

section or the nominal rope diameter are to be preferred because the user normally

only knows the nominal values. Moreover, this has the advantage that the deviation

of the actual to the nominal rope cross-section and rope diameter is included in the

standard deviation of the test results. In the following, the test results are normally

related to the specific tensile force S/d

2

with the nominal rope diameter d.

The wire rope and its lubrication have to be defined precisely, Table

3.2

. In the

following bending tests described here, the wire ropes are normally well lubricated.

For the tests in the Stuttgart Institute, usually a viscous mineral oil was used as a

lubricant, without additives and with a viscosity of 1,370-1,520 mm

2

/s for 40 C.

The sheave diameter D means the distance from rope centre to rope centre as

shown in Fig.

3.33

. The diameter ratio D/d is normally related to the nominal rope

diameter. If not defined otherwise, the sheave is made of steel with a hardened

round groove, a groove radius r = 0.53d (nominal rope diameter) and a groove

opening angle c = 60.

The bending test is completed when the rope or at least one strand is broken so

that the bending test cannot be continued. The number of rope bending cycles

achieved is the so-called breaking number of bending cycles N. In most cases, the

number of bending cycles is recorded as well when a discarding criterion such as

the discarding number of wire breaks B is detected. This number of bending cycles

is called the discarding number of bending cycles N

A

.

During a wire rope bending test, the rope-bending machine is stopped several

times so that the state of the rope bending zones can be inspected. Any change in

the rope bending zones is then recorded, in particular the number of wire breaks is

counted and the rope diameter measured. The number of bending cycles at which

the machine has to be stopped (by the counting device for the machine revolutions)

is normally taken from the Renard row R10. The numbers in this row are: 100,

125, 160, 200, 250, 315, 400, 500, 630, 800, 1,000 multiplied by 10

x

, where x is a

whole number.

Search WWH ::

Custom Search