Civil Engineering Reference

In-Depth Information

The number of wire breaks B and, in some special cases, the rope diameter d as

a function of the number of bending cycles found during the bending tests is used

twice. First of all, for all tests with ropes of the same construction, the number of

wire breaks B

A

is evaluated to find out if the wire rope should be discarded. The

basis for this evaluation is the number of wire breaks B found at 80 % of the

breaking number of bending cycles N. Secondly, the discarding number of bending

cycles N

A

can be recorded based on the number of wire breaks B

A

obtained during

the rope-bending test.

3.2.2 Number of Bending Cycles

3.2.2.1 Tensile Force and Diameter Ratio

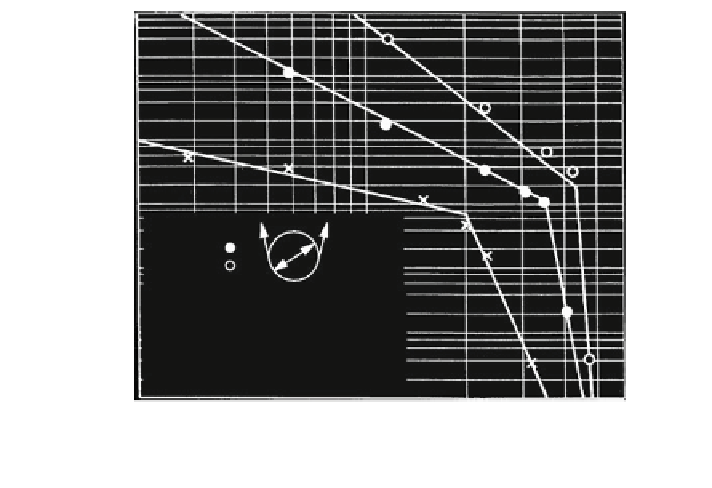

The most important influences on the number of bending cycles are the rope

tensile force S and the diameter ratio D/d (sheave to rope diameter). In Fig.

3.34

,

these influences on the breaking number of bending cycles (simple bending cycles)

are shown for a Filler rope 8 9 (19 + 6F) - NFC - sZ. The breaking number of

bending cycles and the specific rope tensile force are drawn in logarithm scale.

In this diagram form the numbers of bending cycles from the tests form very well

represented by straight lines for constant diameter ratios D/d.

At a certain high tensile force, the number of bending cycles drops abruptly.

The limit of the tensile force where the number of bending cycles begins to drop is

10

7

10

6

10

5

10

4

D/d = 10 x

25

63

D

10

3

Steel hardened, r = 0.53 d

Filler 8x(19+6F)-NFC-B-sZ

R

m

= 1650 N/mm

2

, d = 16 mm

10

2

4

lubricated before test, mineral-oil

2

10

visc. 1370 - 1520 mm

2

/s (40 C)

100 N/mm

2

600

20

30

40 50 70

specific tensile force S/d

2

300

400

200

Fig. 3.34

Breaking numbers of bending cycles for one Filler rope

Search WWH ::

Custom Search