Civil Engineering Reference

In-Depth Information

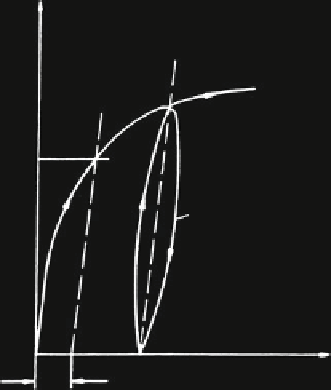

Fig. 1.4 Evaluation of the

yield strength R

p0.2

according

to EN 10002-1

R

p0.2

hysteresis loop

extension

0.2

the wire has to be unloaded and loaded again. As a result, a hysteresis loop occurs

as seen in Fig.

1.4

. A middle line of this hysteresis defines the elasticity module

E = Dr/De. To evaluate the yield strength R

p0.2

, a parallel to the middle line of

the hysteresis has to be drawn through the residual extension e

r

= 0.2 % on the

abscissa. Then the yield strength R

p0.2

is found as an ordinate where the parallel

meets the stress extension line.

To determine stresses, strengths and elasticity modules, the cross-section A of

the unloaded wire has to be measured very precisely. (Unlike EN 10002-1, the

symbol A is used here for the cross-section.) The error in measurement of the

cross-section should be 1 % at the most. For round wires the cross-section has to

be calculated from two wire diameters d measured perpendicular to each other.

To fulfil this accuracy requirement for the cross-section, the wire diameter d

should be measured with a maximum deviation of 0.5 %. With commonly used

measuring instruments this accuracy requirement can only be achieved for thicker

wires. For thin wires and for profile wires, the cross-section can be evaluated by

weighing. With the wire weight m in g, the wire length l in mm and the density q,

the cross-section is then

A

¼

m

l

q

:

ð

1

:

1

Þ

The density for steel is normally q = 0.00785 g/mm

3

. However, because of the

great carbon content of wires used for wire ropes it is to use q = 0.00780 g/mm

3

.

The total extension of steel wires for ropes amounts to about e

t

= 1.5-4 % and

the yield strength R

p0.2

is about 75-95 % of the measured tensile strength R

m

. For

wires taken out of ropes and straightened, the total extension is about

e

t

= 1.4-2.9 % and the yield strength R

p0.2

is about 85-99 % of the tensile

strength R

m

, Schneider and Lang (

1973

).

Search WWH ::

Custom Search