Civil Engineering Reference

In-Depth Information

Table 1.3 Strength of drawn wires out of corrosion resistant steel (excerpt of prEN 10 088-

3:2001, Table

1.8

)

Steel name

Strength range (N/mm

2

)

Steel number

X10CrNi18-8

1.4310

600-800

X5CrNiMo17-12-2

1.4401

900-1,100

X3CrNiMo17-13-3

1.4436

1,000-1,250

X1CrNiMoCuN20-18-7

1.4547

1,400-1,700

X1CrNi25-21

1.4335

1,600-1,900

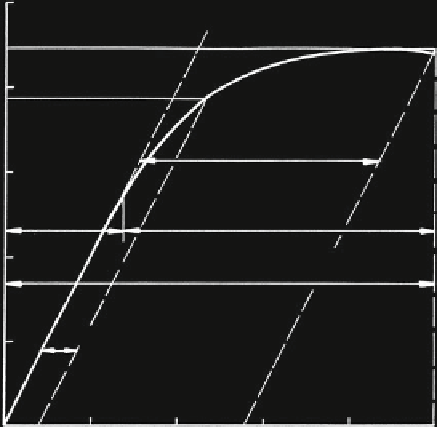

2500

R

m

=2224 N/mm

2

N/mm

2

R

p0.2

=1940 N/mm

2

2000

residual extension

ʵ

r

elastic

extension

ʵ

e

1500

plastic

extension

ʵ

pl

1000

total extension

ʵ

t

ʵ

=0.2 %

500

0

0

0.2

0.5

1.0

extension

1.5

2.5

2.0 %

ʵ

Fig. 1.3

Stress extension diagram of a straightened wire, d = 1.06 mm

However, the yield strength is defined for a small residual extension. Here, the

most frequently used extension is e = 0.2 % and the stress at this point is the yield

strength R

p0.2

. The elasticity module can be evaluated with a special tensile test.

If only the tensile strength R

m

has to be evaluated, it can be done without

straightening the wire. However, if the different extensions and the yield strength

have to be evaluated too, the wire has to be straightened prior to testing. The

measurement starts at a stress of about 10 % of the tensile strength R

m

. Under this

stress, the height of the wire bow at a distance measured of 100 mm should be

smaller than 0.5 mm.

A typical stress-extension diagram of a straightened wire is shown in Fig.

1.3

.

It is possible to take the tensile strength R

m

, the total extension e

t

and the residual

extension e

r

directly from this figure. To determine the elasticity module E and the

yield strength R

p0.2

, the following method has to be used. After a certain yielding,

Search WWH ::

Custom Search