Civil Engineering Reference

In-Depth Information

Table 1.1

Non-alloy steel rod for drawing (excerpt of EN 10 016-2)

Steel name

Steel number

Heat analysis carbon

content (%)

C 42 D

1.0541

0.40-0.45

C 48 D

1.0517

0.45-0.50

C 50 D

1.0586

0.48-0.53

C 82 D

1.0626

0.80-0.85

C 86 D

1.0616

0.83-0.88

C 88 D

1.0628

0.85-0.90

C 92 D

1.0618

0.90-0.95

round

full-locked (Z)

half-locked (H)

trapezoidial (T)

triangular (V)

rectangular (R)

oval (Q)

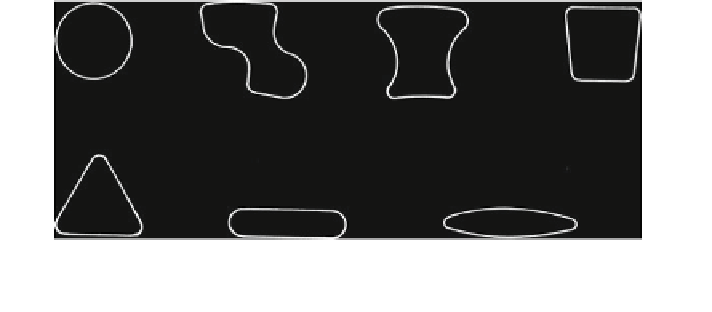

Fig. 1.1

Wire cross-sections for wire ropes

Carbon steels only contain small quantities of other elements. EN 10016-2

gives the following limits for the chemical ingredients of carbon steel rods used for

rope wires: Si 0.1-0.3 %, Mn 0.5-0.8 %, P and S \ 0.035 %, Cr \ 0.15 %,

Ni \ 0.20 %, Mo \ 0.05 %, Cu \ 0.25 % and Al \ 0.01 %. The strength

increases with an increasing carbon content and the breaking extension decreases

if all other influences are constant. Higher contents of sulphur S, phosphorus P,

chrome Cr and copper Cu reduce the steel's ductility, Schneider and Lang (

1973

).

Usually, wires for wire ropes have a round cross-section. In special cases,

however, wires with other cross-sections—called profile wires—are used. The

different cross-sections are to be seen in Fig.

1.1

. The profile wires in the upper

row are inserted in locked coil ropes. The wires below are used for triangular and

oval strands.

In wires with a high carbon content which had been aged artificially, Unterberg

(

1967

) and Apel and Nünninghoff (

1983

) found a distinct decrease in the breaking

extension and the number of turns from the torsion test. The number of test

bendings is slightly reduced and the strength slightly increased. The finite life

fatigue strength is partly increased or decreased.

Bending tests were repeated with three wire ropes after they had been in storage

for 22 years. The original tests were well documented and the new tests were done

Search WWH ::

Custom Search