Civil Engineering Reference

In-Depth Information

in the same way with the usual lubrication. There was virtually no difference in the

rope bending endurance documented for the original tests and the new tests. For

two of these wire ropes, the mean strength of the wires was reduced during the

long period of storage by a maximum of 3 %. For one rope, the mean strength of

the wires increased by 2.7 %.

1.1.2 Wire Manufacturing

After the rod has been patented in a continuous system, the wire diameter is

reduced in stages by cold drawing or cold rolling, rolling especially for profile

wires. Patenting is a heating process. First the wire is heated in an austenising

furnace at about 900 C. Then the temperature is abruptly reduced to about 500 C

when the wire is put through a lead bath. After remaining there for a while,

the wire then leaves the bath and enters the normal temperature of the surround-

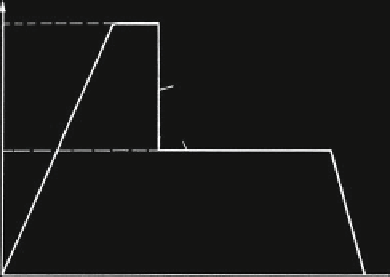

ings. Figure

1.2

shows the course of the temperature during the patenting process.

In recent times, the patenting process has partly been replaced by cooling in

several stages while drawing or rolling the rod, Marcol (

1986

).

By patenting, the steel rod gets a sorbite structure (fine stripes of cementite and

ferrite) which is very suitable for drawing. In the following drawing process, the

wire cross-section is reduced in stages, for example in seven stages from 6 to

2 mm in diameter. After the wires have been patented, they can be drawn again.

The quality of the wire surface can be improved by draw-peeling the wire rod,

Kieselstein and Wißuwa (

2005

).

The principle of the wire drawing was described at an early date by Siebel

(

1959

). The strength increases with the growing decrease of the cross-section by

drawing and at the same time the breaking extension also decreases. The higher the

carbon content of the wires, the stronger they are. For wires with small diameters

below 0.8 mm, the strength can reach about 4,000 N/mm

2

, for thicker wires about

2,500 N/mm

2

, and in all cases the remaining ductility is low. The standardised

nominal strengths of rope wires are

Fig. 1.2 The course of the

temperature in the patenting

process

1100

850

°

C

quenching

lead-bath

600

400

time

Search WWH ::

Custom Search